The Poling Group, headquartered in Akron, Ohio (USA), has gained global recognition for innovation, quality, and customization in the tire testing and rubber industries since David Poling Sr. unified his five separate companies in 2003. Each of the companies making up the Poling Group has a proud history with establishment dates ranging from 1898 to 1978, and the Poling Group has honored that history by keeping the original company names as division names.

ASM Division (1978): The Poling Group's ASM Division specializes in Final Finish Tire Processing, which includes low and high speed Tire Uniformity and Geometry Testing, Grinding, Flash Removal, and Machine Remanufacturing & Retrofit Upgrades.

Firwood Division (1940): The Poling Group's Firwood Division manufactures Tire White Sidewall (or Raised White Letters) Grinders/Buffers, Sidewall Painters, and Post Cure Inflators.

ASF Division (1946): The Poling Group's ASF Division focuses on Rubber Processing, specializing in cold slab stocking cutting solutions, mill blenders, rubber calendering, and batch off equipment.

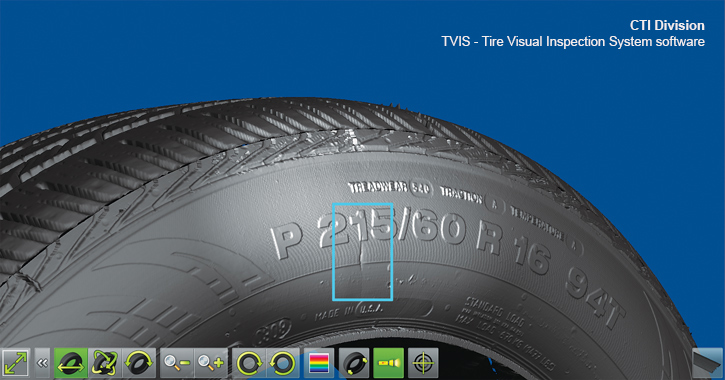

CTI Division (1978): The Poling Group’s CTI Division provides innovative software and electrical controls to the tire industry. Our TTOC6 TUO machine controller is second to none and includes our TDAQ and TSAS products. CTI Division also provides enterprise-level software solutions for Final Finish (FFH) and the entire tire factory (TFFIS), including advanced controls for material handling. They have also been selling PLCIO since 1991 for ultra-fast communications to PLCs from PCs before OPC or Kepware were even born.

Hasbach Division (1898): The Poling Group's Hasbach Division specializes in Laboratory Tire Testing, which includes testing for Endurance, Rolling Resistance, Tire Noise, Force & Moment, and High Speed Uniformity.

Today, the Poling Group continues to refine and perfect their core X-Series TU/Geometry testing machines, while also developing cutting-edge technologies like the TVIS Tire Visual Inspection System, which uses deep learning AI models to automatically identify visual defects in tires. The Poling Group is also introducing their redesigned DB111 Dynamic Balancer with a focus on ease-of-maintenance, latest technologies, production through-put, and uptime.