Chris Bart, director, business development, automotive and tire, Emerson Automation Solutions, explores how monitoring the devices in your curing system can help you reduce tire scrap, improve energy efficiency and avoid downtime.

When it comes to tire manufacturing, it pays to keep things rolling—especially during the critical curing process. Unexpected machine failure during this step not only creates unwanted scrap, but it also drives up costs and affects your overall throughput. Fortunately, one simple way to avoid these setbacks is to monitor the health and performance of your curing system.

Typically, the only elements monitored during curing are the temperature in the mold, as well as the total time the tire spends in the mold. But extending these capabilities to other components in the system would benefit your entire manufacturing operation. For example, monitoring your steam trap for signs of wear can help you prevent valve and piping damage while improving your overall energy efficiency.

Fortunately, device monitoring has never been easier. Many components, including pneumatic valves, air filtration systems and steam traps, now integrate diagnostic capabilities that provide you with valuable health and performance data. These insights can help you implement predictive maintenance strategies, lower the amount of scrap and avoid costly downtime during curing—keeping your tires rolling off the production line.

Monitoring valve health improves tire quality

Monitoring valve health improves tire quality

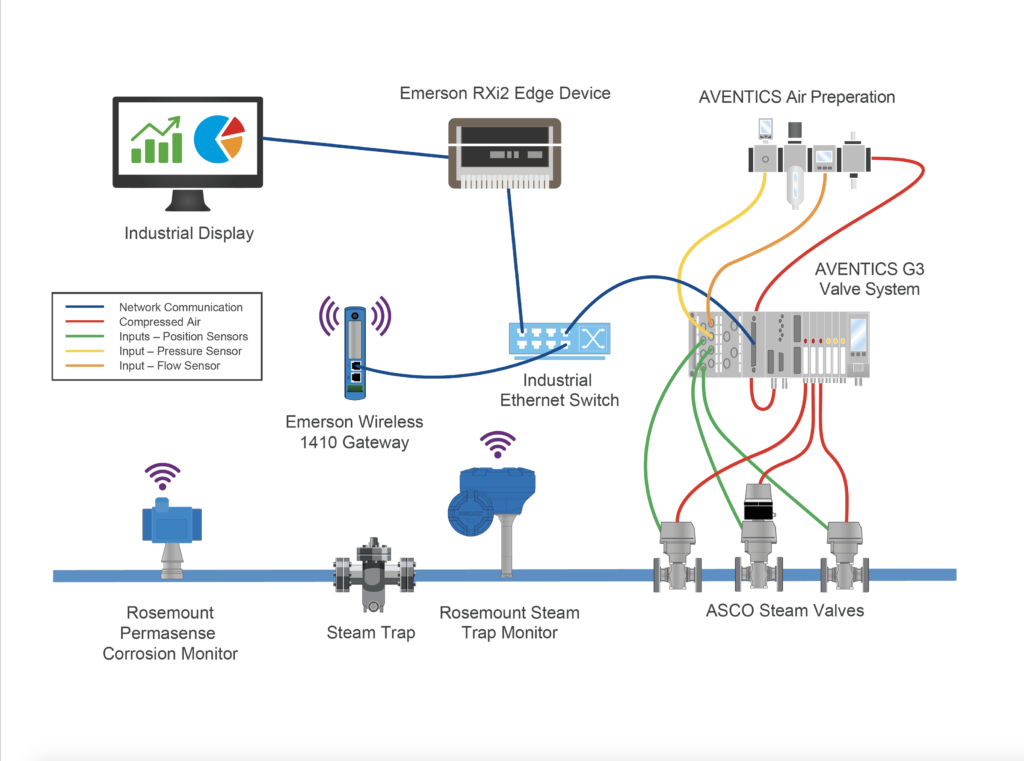

Automated monitoring systems typically include field-level sensors, a wired or wireless communications network and an edge device that brings together performance insights. This system is designed to gather and analyze component data, which in turn allows you to take meaningful steps to avoid machine failure during the curing process.

Your valves are one of the most important components to continuously monitor, as they play an important role throughout the entire tire-making operation. For example, pneumatic directional control valves ensure your wire and fabric calendars, extruders, tire-building machines and curing presses operate efficiently.

They also control the pneumatic aspects of these processes, including pressure-operated steam valves, cylinders and actuators. In addition, pressure-operated valves control critical steam and bladder inflation. They also enable rapid cycling and tight shut-off of air, keeping your tire presses running smoothly.

Because damaged valves can lead to substandard tires and produce costly, late-stage scrap, it makes sense to monitor the health of these components around the clock. Fortunately, new fieldbus technologies have made this process easier than ever. The Aventics G3 Electronic Fieldbus System brings diagnostic functionality to valve manifolds, allowing you to identify possible issues before it’s too late. For example, an increase in valve travel time may indicate possible wear. Equipped with this information, you can then take steps to schedule maintenance to prevent valve failure during production cycles.

By spotting potential issues early, solutions like G3 support predictive maintenance strategies, leading to lower maintenance costs, less downtime and higher throughput. And best of all, G3 is simple to assemble, install, commission and maintain. Its functionality allows programmable logic controllers (PLC) to more efficiently turn valves on and off, as well as channel data from valves, sensors and other I/O devices via your industrial network.

Improve energy efficiency with air filtration system sensors

During the tire curing process, air preparation and filtration systems, such as coalescing filters, purify the compressed air by removing dirt particles, moisture and oil—preventing debris and other contaminants from reaching the machinery. If compressed air isn’t properly filtered, your equipment won’t function correctly and your valves can wear or even fail prematurely.

Many air preparation and filtration components now integrate condition monitoring capabilities that issue alarms if the coalescing filters are clogged. Clogging reduces the air pressure downstream, causing the compressor to generate air at a higher pressure and driving up your energy usage and operating costs. Many of these modular components also monitor air flow, pressure and temperature in the feedline, providing you with advanced diagnostics on the system’s operating parameters. Knowing this information can help you manage your energy consumption, reduce costs and extend the life of your valves.

Avoid equipment damage with steam trap monitoring

Avoid equipment damage with steam trap monitoring

Another way to lower your energy bills is to monitor the steam trap. Steam is a major energy expense in tire curing, and even the slightest dip in efficiency can cost you thousands of dollars. Steam traps are self-contained valves that automatically drain water without allowing steam to escape. It’s important to ensure these devices are always performing correctly; if a steam trap jams in an open or partially open position, large amounts of steam can escape. On the other hand, if the steam trap sticks in a closed position, the water won’t drain, eventually damaging the valves and pipework.

Steam traps are usually monitored manually through periodic inspections—a time-consuming process that requires manpower. Fortunately, you can now deploy wireless acoustic transmitters that monitor steam trap health and detect failures in real time. Compared with periodic inspections, this automated option lets you take a proactive approach to your steam traps, which in turn prevents equipment damage and improves your overall energy efficiency.

Enable easy data collection and analysis

It’s not enough to simply deploy components with integrated diagnostics and condition monitoring capabilities; you need an edge device to collect all the data and make it available to your operators on the machine floor. This is where edge computing devices like the RXi2 Industrial PC come in. This rugged IPC from Emerson collects and analyzes data from your pneumatic valves, air filtration systems and steam traps and then presents this information to personnel on an easy-to-read industrial display.

Many edge devices take these capabilities even further. Take the Emerson CPL410 edge controller, for example. This intelligent, multicore controller combines real-time deterministic control with open source Linux technology to securely connect to, collect and analyze industrial data directly at the machine. It also minimizes the number of control devices you need on the factory floor—enabling tire manufacturers to reduce the footprint of their operations in accordance with environmental regulations.

Maximize your tire throughput today

Unexpected machine downtime during the tire curing process not only increases your operational costs, but also severely affects your ability to meet production targets. Fortunately, it’s never been easier to implement monitoring devices with diagnostic capabilities that keep your pneumatic valves, air preparation and filtration systems and steam traps running smoothly and efficiently.

To learn more, please visit Emerson.com/tires.