The energy lost by a rolling tire appears as heat which can be measured using a variety of temperature sensing techniques. The accuracy of this can vary from within 3°C to better than 0.1° and with a resolution as fine as 0.01°. Remote sensing of the liner temperature using an infrared pyrometer is almost certainly both the easiest and the most accurate transducer to use. This statement is definitely true if many tires are to be measured and their results compared. Most other sensors involve a wiring loom, slip rings or other components that are difficult to install. The tire cavity thermometer (TCT) adds less than five minutes to the tire fitting time.

The results presented are from recent measurements using a TCT set up to scan the tread from shoulder to shoulder. The data provides detailed information on temperatures and temperature gradients across sections of the tire in a grid of 16 x 4 pixels. The test tire was a 235/70 R15 all-terrain tire running in a temperature controlled test cell at 25°C. The running conditions were 100km/h, 2.2 bar and 80% load on a smooth 1.7m steel road wheel.

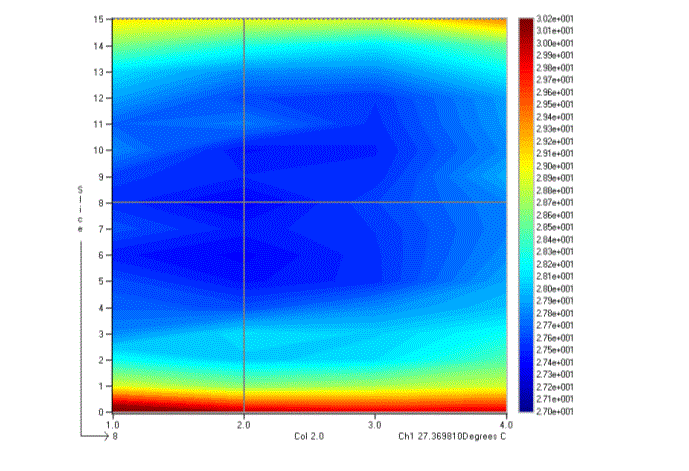

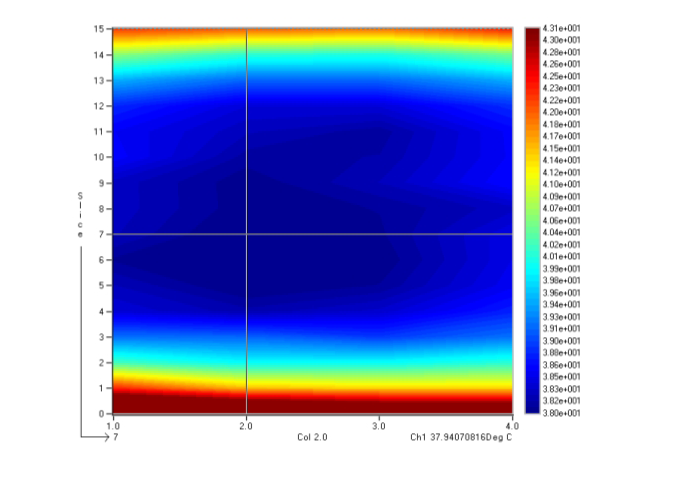

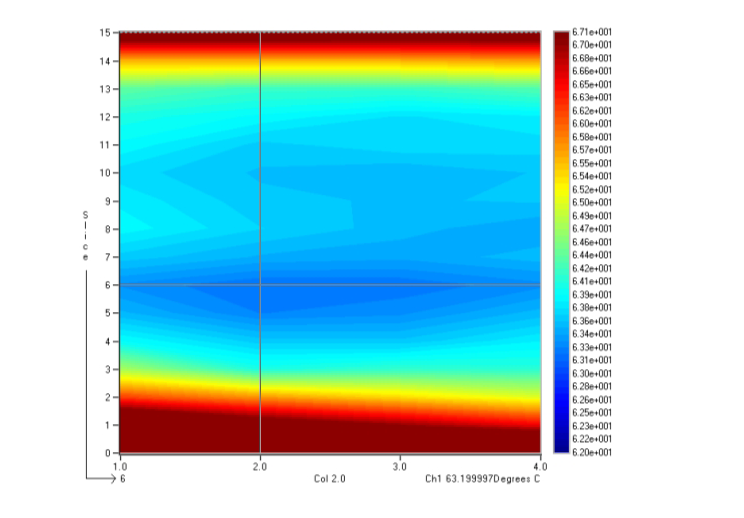

The first color map shows the tire as the run commences with a 3°C temperature gradient established between the shoulder and the tread center (Figure 1). As the run continues, the whole of the tire rises in temperature and the gradient from shoulder to tread center increases to 8°C (Figure 2). After 25 minutes, the rate of temperature increase reduces; it is now at 68°C and the temperature gradient has reduced from 8 to 5°C (Figure 3). The tire was left running until there was no further increase in temperature; the terminal temperature was 75°C at the shoulder.

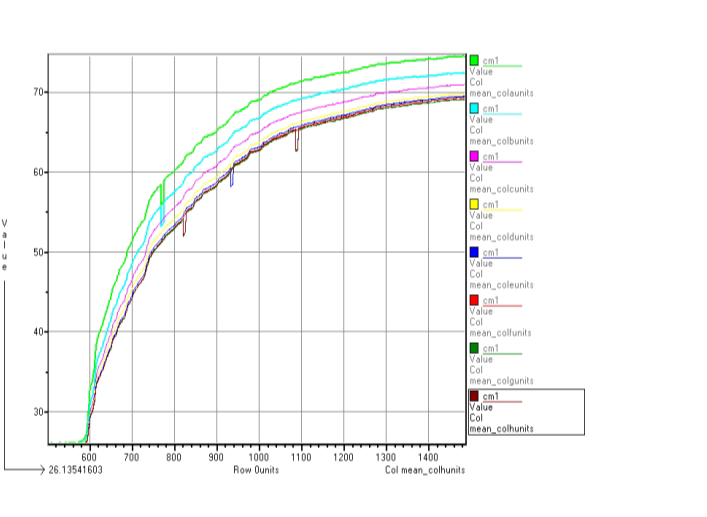

The temperature gradient was steepest over the two pixel columns next to the shoulder, that is, over just 30mm, with the bulk of the tread being represented by 5 pixel columns on either side of the center line of the tire, that is, a width of some 200mm. This 200mm remained predominantly at the same, though uniformly rising temperature for the whole run is shown (Figure 4).

The accurate temperature mapping for a running tire reveals in detail what is happening during the time a tire runs up to full operating temperature. For tire development engineers, there is a clear advantage in being able to study how a small change to construction affects the thermodynamics and the rolling resistance of a tire.