Dr Malal Kane introduces IFSTTAR’s software tool that predicts the skid resistance of a tire on a given road surface, ahead of his presentation at the forthcoming Tire Technology Expo Conference in Hannover, Germany.

Dr Malal Kane introduces IFSTTAR’s software tool that predicts the skid resistance of a tire on a given road surface, ahead of his presentation at the forthcoming Tire Technology Expo Conference in Hannover, Germany.

What is the background of your presentation?

Skid resistance is one of the important parameters of tire performance, but the physics behind it is extremely complex due to the numerous and interrelated factors affecting the phenomenon. For example, the skid resistance will depend as much on the pavement texture as on the rheological behavior of the tire rubber.

Furthermore, water on the road acts as a lubricant, which makes the physical modeling very complex. I will introduce a new prediction tool for tire-road skid resistance, based on modeling the dynamic viscoelastic rough-lubricated contact.

Tell us more about the prediction tool.

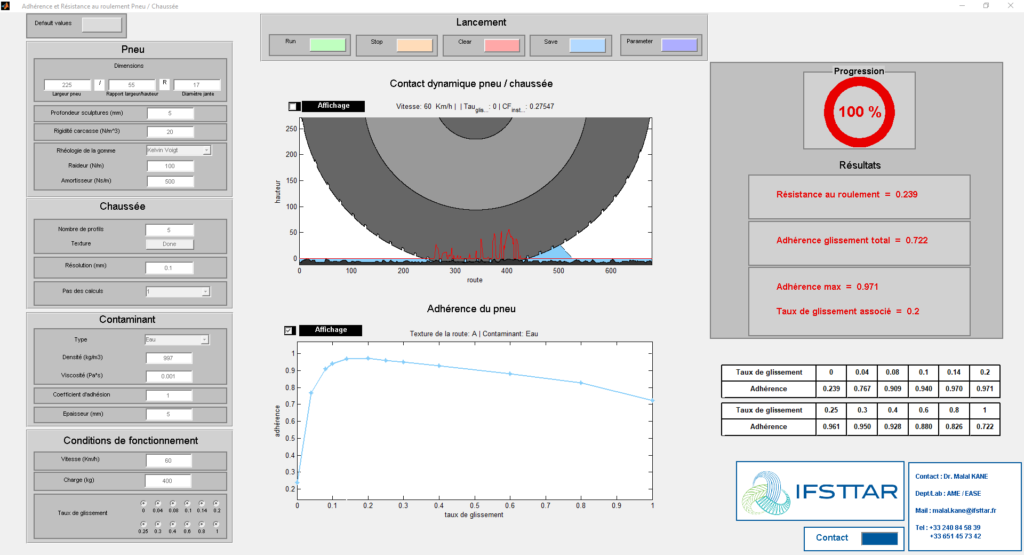

The tool we’ve developed is one of the most complete of its kind, because it takes into account all parameters related to tire, road and contact operating conditions. On the tire side, it takes into account the tire’s geometry (width, rim diameter, flank height, tread pattern and depth), inflation pressure and rubber material (viscoelasticity). The latter is simulated using its rheological model.

On the road side, it takes into account the surface texture via the surface topography. Modeling the contact interface, the tool models dry or wet conditions via the lubricant depth, viscosity and density. The operating conditions are taken into account via the load, speed and slip ratio of the tire.

We’ve validated the tool by performing braking tests with a passenger vehicle at different speeds on wet roads of different textures. It correctly predicted when the wheels would lose grip, both with ABS in operation, and with the system disabled. The trend of the results in wet conditions was similar to what we’ve seen in experiments in dry conditions, so it’s safe to conclude that the tool can handle both wet and dry roads.

We’ve developed the tool to have capabilities beyond skid resistance. When setting the slip rate at 0%, it can also predict rolling resistance, and by adding some code that relates the contact parameters to data about air pumping, the tool can even be made to predict road noise. This will make it a complete surface design tool for road builders and road safety. Especially in the context of future autonomous vehicles, our tool could be very valuable since it will allow the vehicle’s algorithms to consider the available grip when calculating safe following distances and which maneuvers are possible.

How can road builders and tire manufacturers use this tool?

As a simulation tool, the software can assist road builders in choosing aggregate types and designing the wearing course of roads. It can help them achieve the right texture that meets goals for skid resistance. Tire manufacturers can use the tool to optimize tires’ skid resistance on a given road surface. When they know the surface’s texture, they can run simulations instead of having to do physical testing with different rubber formulations to find out which one performs the best.

What’s next for this research?

We will share the tool with academics, tire manufacturers and road builders. It’s already mature enough to be used for research, but we hope to get feedback from them to further improve the tool. There are two areas in particular where we still want to improve the software. The first challenge is to refine the calculations that pair the local deformations of the tire tread on the roadway’s surface asperities to the hydrodynamic lift caused by water. The other challenge is to boost the speed of the calculations. To do this, we want to simplify the model as much as possible, and that means avoiding finite element calculations, which use up a lot of time and resources.

Malal’s presentation will be part of the ‘Tire Technology for the Vehicle Revolution’ stream on Day 2 of the Conference. View the full program here and book your delegate pass now to get 15% off.

Malal’s presentation will be part of the ‘Tire Technology for the Vehicle Revolution’ stream on Day 2 of the Conference. View the full program here and book your delegate pass now to get 15% off.