A new, non-destructive, rapid tire deflation test system has been launched by Koala Technologies (KTL). Te.Sense Bloom is fully compliant with FMVSS 110 and emerging EV stability test standards, and serves as a reusable tool to help OEMs and tire manufacturers optimize their test programs and reduce waste. The first US specification kit has been delivered to the Transportation Research Center in Ohio for initial evaluations.

Rapid tire deflation tests often involve driving a vehicle over special roadway cleats at defined speeds. With this method, tires are destructively punctured and destroyed by the cleats, and internal inflation pressure is quickly reduced to atmospheric pressure. Sometimes the purpose of these tests (such as with FMVSS 110) is to ensure that tires stay safely seated on the wheels after rapid deflation; in other cases, the test measures and evaluates vehicle lateral stability criteria during tire failure events.

The roadway cleats used typically destroy multiple tires – for instance, both right-side tires would be punctured by the same cleat, even when only the front tire requires testing. This more costly and wasteful double-puncture effect not only destroys more tires than needed, but it may also corrupt certain vehicle dynamics tests that call for a single, targeted tire failure.

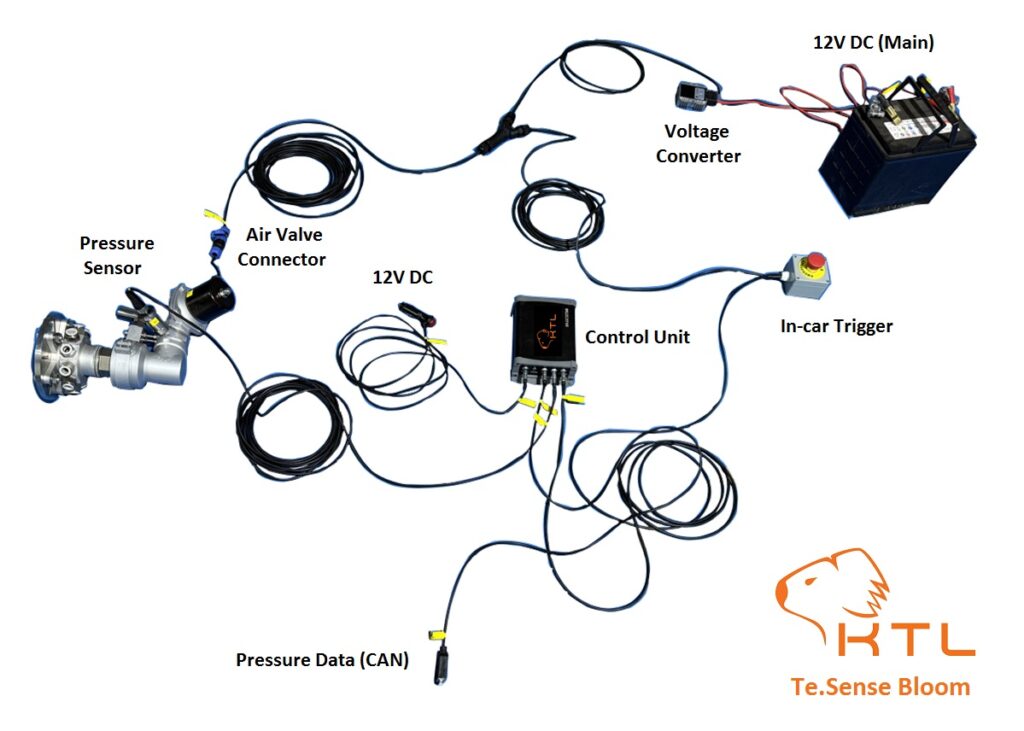

Te.Sense Bloom offers a non-destructive solution for controlled, rapid deflation of selected tires. The device uses a central air ejector valve with adjustable volume and flow, simulating a sudden tire pressure loss event.

Te.Sense Bloom offers a non-destructive solution for controlled, rapid deflation of selected tires. The device uses a central air ejector valve with adjustable volume and flow, simulating a sudden tire pressure loss event.

While using air valves for vehicle and tire testing is not new, KTL‘s innovation lies in making Te.Sense Bloom a turn-key solution for automotive testers and engineers. It provides a repeatable setup, easy in-car operation and simple integration with data acquisition systems. KTL also offers a wheel setup service to streamline test preparations.

Te.Sense Bloom thus eliminates many of the recurring costs typically associated with this type of testing. Starting at US$20,000 for base kits, customers can invest in a portable, reusable test system that gives them full control over test schedules and methods.

Te.Sense Bloom enables a rapid tire deflation event to be triggered either from inside the vehicle or remotely, offering more flexibility in test scenarios. It is designed for testing tire inflation pressures up to 100psi and speeds up to 140km/h (87mph). Te.Sense Bloom captures precise, real-time tire inflation pressure data at 100Hz, with an accuracy of +/-0.1psi. This enables detailed analysis of tire and vehicle responses during rapid tire deflations, which occur in less than 750ms.

Kenneth Martin, head of tire testing at the Transportation Research Center, said, “We have significant experience with rapid tire deflation tests, using all types of methods, and we’re looking forward to evaluating KTL’s Te.Sense Bloom, since it represents a turn-key, non-destructive solution.

“There’s definitely some baseline justification for test equipment like this because it fundamentally means consuming fewer tires. But Te.Sense Bloom’s inherent connectivity opens some other doors also, since triggered and monitored rapid tire deflations are becoming an area of interest for vehicle stability testing, especially in EV space.”

In addition to meeting FMVSS 110 requirements, Te.Sense Bloom complies with several emerging electric vehicle stability testing standards. In some markets, like China, EV lateral stability tests with failed tires – both with and without drive motor engagement – are already mandatory. Unlike cleat testing, which can affect multiple tires, certain EV stability tests require targeting individual tires to ensure failsafe compliance.

Te.Sense Bloom is already being used by Chinese OEMs and automotive system providers such as Huawei AITO, SAIC Motor Corp and GAC Motor to perform regulatory tests, including GB/T 38796-2020 (Performance Requirements and Test Methods of Automobile Blow-out Emergency Safety Device).

KTL founder and president Mike Lee said, “Koala Technologies is excited to introduce Te.Sense Bloom into new markets, beginning in 2025. Bloom has been widely adopted for vehicle development testing in China over the last several years, becoming a must-have tool for many OEMs and key suppliers. It’s one example, among many, of an excellent, trusted, useful automotive testing device that no-one knows about outside China.

“A part of our mission at KTL is to shine a light on some of these exciting technologies that are currently available, but not widely known. Another part of our mission is to help customers achieve their goals more efficiently and at a lower cost. We look forward to the upcoming testing at the Transportation Research Center in Ohio, and we hope that Te.Sense Bloom proves to be a good fit for automotive development programs in the US and beyond.”