Researchers at the University of Waterloo in Ontario, Canada, have developed a new approach to tire modeling using Maplesoft’s MapleSim software.

Head researcher Dr Joydeep Banerjee explained, “The volumetric tire model developed in MapleSim offers two distinct advantages over existing tire models. As the moments are calculated using kinematic data only, the model can be easily programmed for numerical simulations. In addition, the resistive torques are evaluated as functions of both normal load and angular speed of the wheel.”

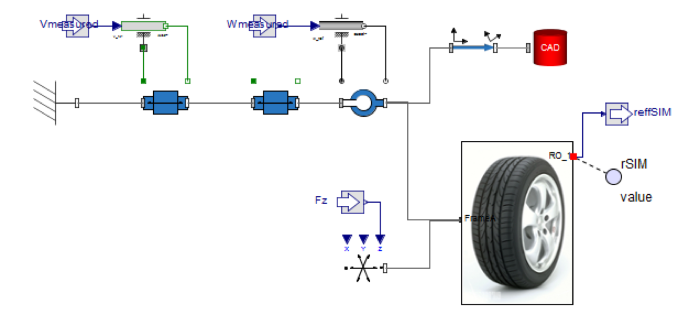

Using Maple, Maplesoft’s advanced computation engine, the symbolic expressions for the normal force and rolling resistance were derived as a function of the position and orientation of the tire. The distributed friction forces were symbolically integrated over the tire contact patch to calculate the traction forces and self-aligning moments. The researchers then used MapleSim to develop the model using custom components derived from the Maple expressions.

To test the accuracy of the volumetric tire model, the model was used in a simulated drop test. A real-life drop test was performed on a Michelin 195/65 R15 summer tire inflated to 33psi. The tire model was assembled to undergo the same motion as the physical drop test. Using MapleSim, the drop and rebound of the tire were simulated. Another commercially available tire model, selected from MapleSim’s extensive tire library, was also used to compare the results. When comparing the results of the two models, the MapleSim volumetric tire model provided a slightly more accurate estimate for the position of the wheel.

Initial results indicate that the MapleSim volumetric tire model is promising for use, not only for automobile tires, but for tires with higher camber angles, such as bicycle and motorcycle tires. To increase the fidelity of the model, the researchers plan on further testing of the volumetric tire model using data obtained from a vehicle measurement system (VMS). The VMS will provide information on the position, orientation and loads placed on the tire during actual driving tests of a vehicle.

“While the initial results from the model look promising, the data from the VMS can be used to further fine tune the parameters of the tire model. Using MapleSim, we can take the analysis further by easily incorporating the tire model into detailed vehicle models for complete vehicle systems simulations,” said Dr John McPhee, Prof. of Systems Design Engineering.

June 29, 2017