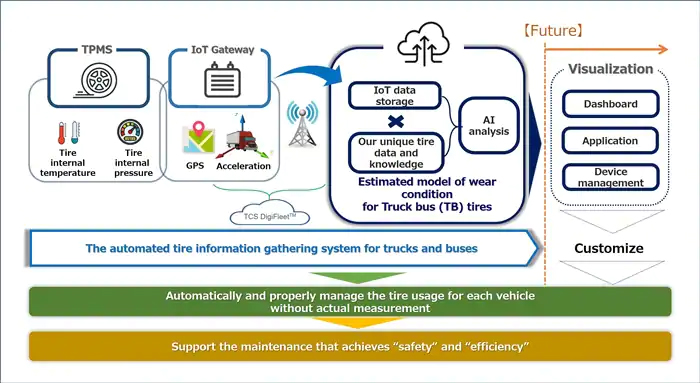

Physically monitoring the condition of tires in use, beyond simple pressures and temperatures, is a current hot topic for tire manufacturers, particularly in the commercial vehicle sector. Toyo has responded with the development of an AI-based system that models tire condition in real time, based on a combination of data from sensors combined with weather, manufacturing and vehicle duty cycle information.

The most common means of measuring tire condition is through operators physically checking parameters such as tread depth. Toyo says that its new system will reduce the need for time-consuming physical checks and thus increase efficiency for fleet managers.

Although it is possible to visually monitor the condition of tires using systems such as thermal imaging, the hardware needed is expensive and needs to be integrated with existing vehicle systems. Toyo’s system relies primarily on data from TPMS equipment, which is standard on many vehicles, combined with specific data on the tire types fitted and GPS information on speed, acceleration and travel distance.

The company points out that the amount of wear and the aging patterns of tires vary considerably depending on the service details of a specific vehicle, and thus the GPS data is a vital element in any predictive model. The estimation model combines all of this data and uses AI to analyze it, drawing a prediction on the likely state of tire wear across a vehicle’s axles.

Toyo says it worked with a number of partners on development of the system, including Nihon Tata Consultancy Services on the hardware and SAS Institute Japan on the predictive model.

The concept is still in the development stage, but Toyo hopes to roll it out as service in the near future.