After the conclusion of an extensive 12-month testing phase, Continental has begun operations with its new driving simulator for tire testing, which will be used for the development of new tires, especially for OEMs. The adoption of virtual tire tests is expected to bring about resource savings and a reduction in development times.

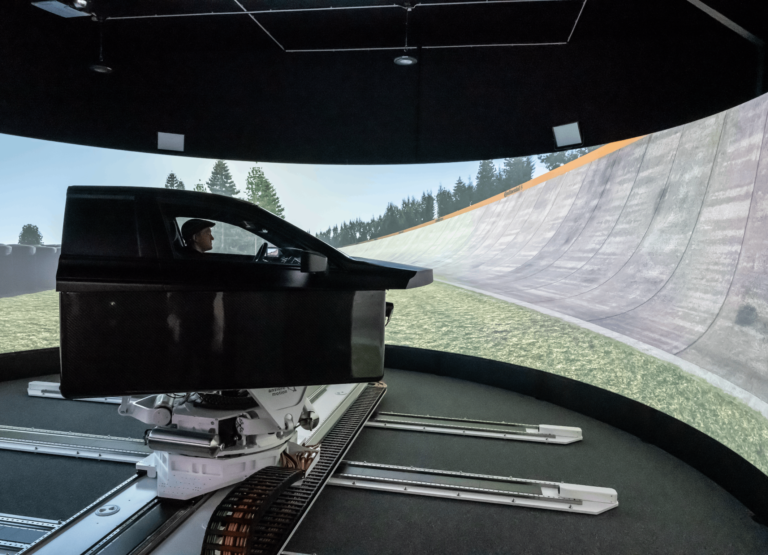

The driver-in-the-loop simulator (DIL) accurately calculates the driving dynamics parameters for both tires and the test vehicle. With its high maneuverability, the simulator enables Continental’s professional test drivers to experience subjective driving impressions comparable to those derived from traditional tire tests on an actual test track. This practical approach aims to streamline tire development by leveraging virtual testing methods.

Bernd Korte, head of passenger tire development for Continental’s original equipment business, said, “Virtual development methods enable us to offer solutions even more efficiently and more precisely tailored to the needs and requirements of our customers. Virtual test kilometers also play a major part in conserving valuable resources.”

In the virtual test, the simulator calculates the exact driving dynamics parameters for the tires and the corresponding test vehicle. Continental loads the relevant tire model for the customer’s specific vehicle model into the simulator. The tire model contains precise information on the tire design, tread and rubber compound; the test driver thus drives a dedicated tire model for a specific vehicle model variant, as was previously the case on the physical test track.

The simulator allows the evaluation of tires for various vehicles, including passenger cars and commercial vehicles, as well as electric, hybrid, and combustion-engine vehicles. An important feature is the digital adjustment of tire parameters, enabling quick repetition of test drives and direct comparison of subjective driving impressions.

The extensive motion platform, measuring 4m in length and 5m in width, with a maximum acceleration of 12m/s, provides test drivers with the full six degrees of freedom in vehicle dynamics. This mimics the experience of driving a real vehicle on a physical test track, incorporating longitudinal and lateral movements, stroke movement, yaw, pitch, and roll. Professional test drivers, trained to integrate these subjective driving impressions, play a crucial role in developing the precise tire setup needed for specific vehicle models as required by manufacturers.

“With our driving simulator, we evaluate and optimize a tire before we physically build it for the first time,” explained Julian Kroeber, who is responsible for the tire simulator at Continental. “This allows us to further optimize our development process. It also saves a lot of time for our customers.”

New materials that are being used in a tire for the first time can also be tested extensively in the new simulator.