Michelin says it has committed to making all of its tires 100% sustainable by 2050. It notes that 30% of the components used for its current tire production are already sourced from natural, recycled or sustainable raw materials, but aims to push this percentage higher in the coming years.

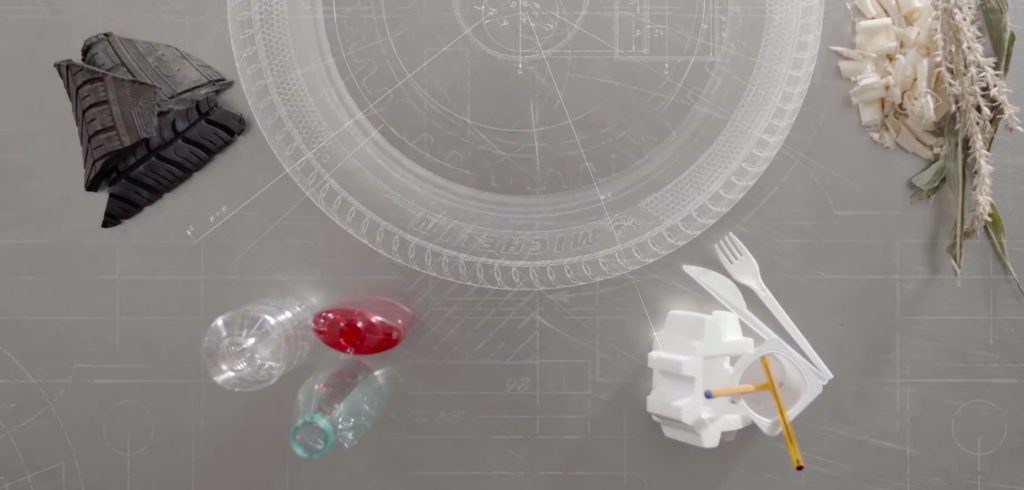

Though the main component of most tires is natural rubber, Michelin points out that they also include synthetic rubber, metal, fibers and components that strengthen a tire’s structure, such as carbon black, silica and plasticizers (resins, etc). The tire manufacturer states that its team of over 6,000 engineers, working across seven research centers, is striving to replace these myriad components with sustainable alternatives.

Michelin says it is also aware that the speed and nature of innovation require new forms of cooperation, which is why it has forged partnerships with companies and startups whose specialisms range from materials development through to the second-life use of tires.

For example, Axens and IFP Energies Nouvelles are two companies that are spearheading the BioButterfly project, supported by Ademe (the French Agency for Environment and Energy Management). They have been working with Michelin since 2019 on producing bio-sourced butadiene to replace petroleum-based butadiene. Using the biomass from wood, rice husks, leaves, corn stalks and other plant waste, 4.2 million tons of wood chips could be incorporated into Michelin tires every year.

Similarly, Michelin has a partnership with Canada-based Pyrowave, which produces recycled styrene from plastics found in packaging. Styrene is an important monomer used to manufacture not only polystyrene but also synthetic rubber for tires and a wide variety of consumer goods. Eventually, several tens of thousands of tons of polystyrene waste could be recycled back into its original products as well as into Michelin tires every year.