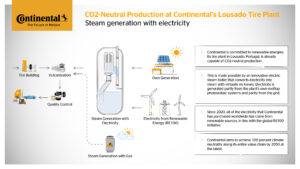

Continental has initiated CO2-neutral tire production at its Lousado plant in Portugal, as part of its goal of achieving completely CO2-neutral production by 2040. The Lousado plant has an annual production capacity of more than 18 million tires and uses an electric boiler that generates steam from green electricity rather than natural gas.

The new electric boiler converts solar and other renewable electricity into steam with minimal losses. Water is pumped from the bottom of the boiler to the top, sprayed onto electrodes and heated by electric current until it evaporates into steam. This process is essential for vulcanization, which turns raw rubber into flexible and elastic tire rubber.

A conventional gas boiler remains in place at the Lousado plant to ensure flexibility in response to the fluctuating availability of renewable energy. This hybrid approach is designed to help maintain stable and sustainable production processes, especially during the winter months when solar energy is less abundant.

“In Lousado, we are demonstrating that even very large tire plants can achieve CO2-neutral production. To do so, the availability of renewable energy sources at competitive prices is crucial,” explained Dr Bernhard Trilken, head of manufacturing and logistics at Continental Tires. He added, “We are preparing all our plants so that they can use as much renewable energy as possible. The commissioning of our electric steam boiler in Lousado is the start of an exciting learning curve.”

The Lousado plant has been operational for over 30 years. It produces tires for cars, agricultural machinery and off-road vehicles. It is also the production site for the UltraContact NXT, which Continental says is its most sustainable series tire to date.

“Our site in Lousado benefits from the fact that the sun shines frequently. This enables us to achieve a fully electrified and CO2-neutral tire production process whenever possible,” said Pedro Carreira, head of the Lousado plant.