Bridgestone Americas (Bridgestone) has formed an exclusive partnership with LanzaTech NZ (LanzaTech), a carbon capture and transformation (CCT) company, to address end-of-life tire waste.

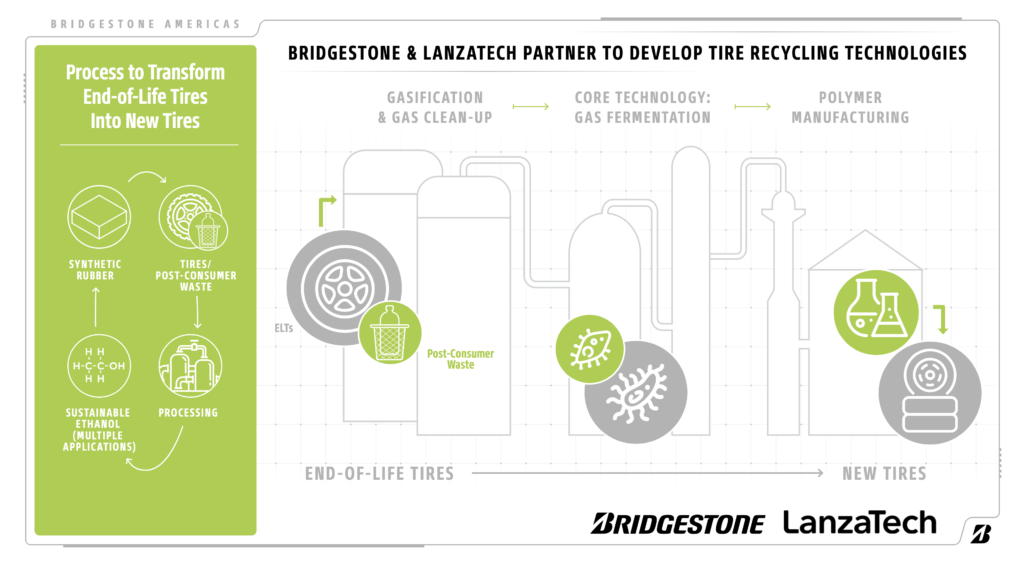

Under the partnership the duo will co-develop the first dedicated end-of-life tire recycling process by using LanzaTech’s own CCT technology, with the aim of creating a pathway toward tire material circularity and to decarbonize new tire production processes.

With more than one billion tires reaching end-of-life globally each year, the pair will address the major international issue by converting end-of-life tires into new materials. Bridgestone and LanzaTech will also investigate new processes to create sustainable synthetic rubber which does not rely on petrochemicals.

The newly formed partnership seeks to develop a new business model that will create a post-consumer waste management strategy for end-of-life tires, while simultaneously driving the increased adoption of sustainably sourced chemicals for commercial applications.

By applying LanzaTech’s carbon capture and gas fermentation process to end-of-life tires, sustainably produced chemicals such as ethanol can be yielded which can then be converted into materials such as PET for packaging, polyester yarn and surfactants used in consumer home goods. Both Bridgestone and LanzaTech will also explore further opportunities to co-develop proprietary microbe technology to produce more efficient pathways to produce butadiene needed for new tire production, thus creating circularity for end-of-life tires.

Based in Skokie, Illinois, LanzaTech transforms waste carbon into new materials such as sustainable fuels, fabrics, packaging and other products. The company’s main aim is to challenge and change the way carbon is used globally, nurturing a new circular carbon economy where carbon is reused instead of wasted.

“We are excited to join forces with LanzaTech to co-create a more sustainable pathway for end-of-life tires,” said Paolo Ferrari, president and CEO, Bridgestone Americas. “The steps we take today are determining the health of our planet for future generations. We are determined to meet the moment with sustainable innovation that transforms the way tires are made and promotes end-to-end material circularity.”

“LanzaTech and Bridgestone are working together to find solutions to some of our world’s greatest challenges,” commented Dr Jennifer Holmgren, chief executive officer, LanzaTech. “We have already proven that we can convert unrecyclable, unsorted municipal solid waste to ethanol and then make products we use in our daily lives. With our partnership with Bridgestone, we are developing a circular pathway to use tires to make tires. This partnership exemplifies what we call a Post Pollution Future.”