Michelin North America has announced the launch of two new pre-mold retreads to expand the manufacturer’s portfolio of tire retread technologies. The first, the Michelin X Multi T-SA Pre-Mold Retread, is designed to provide a solution for vehicles in spread axle and tag axle applications experiencing scrub and stresses, alongside improving the mileage performance of regional and super-regional vehicle operations. The second, the Michelin X One Line Energy T2 Pre-Mold Retread (pictured above) has been developed to lower the total cost of ownership for North American line-haul markets, alongside improved trailer tread wear and fuel efficiency.

“Fleet managers are under pressure to have well-managed tire programs, yet some managers may be pressured into selecting low-priced tires instead of high-quality retreads,” commented Adam Murphy, vice president of B2B marketing at Michelin. “The smart money is on retreads. Retreading plays the central role in delivering the lowest total tire program cost and creates the greatest return on a fleet’s tire investment. In addition, manufacturing a retreaded tire requires 15 gallons less oil and approximately 90-100 lb [40-45kg] less total material than a new tire, so the environment also benefits.”

Aimed at regional and super-regional operations, the X Multi T-SA features a newly developed rubber compound said to enhance scrub resistance and wear rate while the tire’s rounded, solid shoulder provides further resistance. The retread provides maximum tread-to-shoulder adhesion in high scrub applications and is stated to provide up to 25% more mileage. Other improvements to the company’s latest product include groove-bottom protectors to protect against stone drilling. The product will be available with a deep 16/32in tread depth in six tread base widths – 185/225, 195/235, 205/245, 215/255, 225/265 and 245/285.

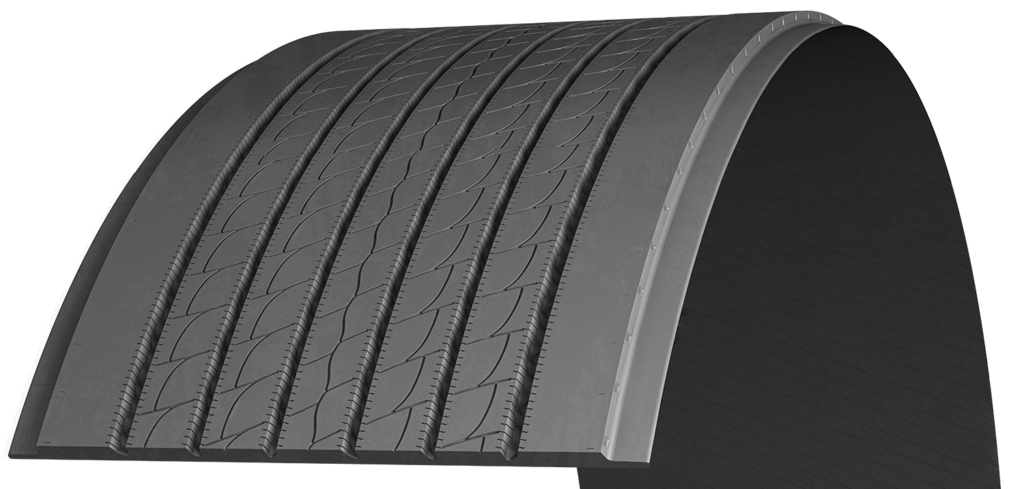

The Michelin X One Line Energy T2 Pre-Mold Retread replaces the tire manufacturer’s previous iteration, the X One Line Energy T Pre-Mold Retread. Said to provide excellent handling, the microsipes and the solid shoulder of the X One Line Energy T2 aid in reducing uneven wear. The trailer-position retread offers increased fuel efficiency through a new compound tread for a lower total cost of ownership, and a winged tread provides maximum shoulder adhesion. Furthermore, waved grooves help prevent stone drilling and wide grooves improve water evacuation. Meeting SmartWay standards, the retread will be available from July 1 in a 375/425 tread base width with a 13/32in tread depth.