Sumitomo Rubber Industries (SRI) and Ibaraki University, Japan, have pioneered a technique to accurately observe individual compounds in a tire’s structure, to help with future tire development.

Through the use of a newly designed particle beam microscope developed at Ibaraki University, a team of researchers and engineers has been able to observe and analyze individual materials in a tire’s compound for the first time. The team claims that the research offers a wealth of information that can be used to develop high performance tire’s with high levels of efficiency and wear resistance.

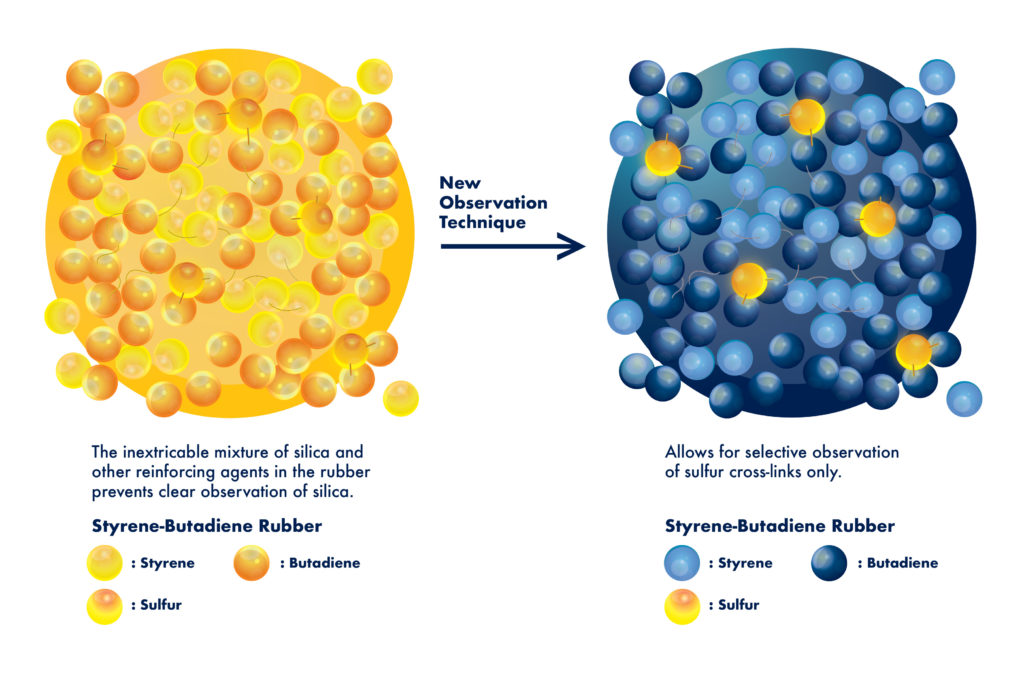

Until this new development, researchers have been unable to observe hierarchal structures in a tire’s compound, such as sulfur cross-links that give rubber elasticity and have long been thought to be linked to strength and degradation. The particle beam microscope is capable of evaluating mass-produced tire rubber samples. It generates a clear image of the sample showing an accurate breakdown of elements or reinforcing agents using individual colors to clearly identify each element.

Dr Bernd Löwenhaupt of Sumitomo Rubber Europe said, “Being able to evaluate the very structures of tires themselves, provides us with image data that can be used to develop internal structures for future tires that provide superior performance in terms of fuel efficiency, wear resistance and so forth. This breakthrough offers enormous potential for the acceleration of our material development process.”