Tire machinery manufacturer 4JET and laser specialist Jenoptik’s Light and Production Division are looking to commercialize a collaborative laser prototyping technology.

The companies say the new laser technology will enable manufacturers to prototype vehicle tires at a much faster rate thanks to more precise laser material processing. The process involves using a laser to cut individual profiles and designs into a completely smooth tread and neutral sidewall. When compared with the manual carving of tires, it is said the new process shortens tire development cycles and reduces prototyping costs.

Developed by Jenoptik, the laser ablation technology should help tire manufacturers to increase diversity within product lines while also allowing for the faster production of design samples and pre-production tires. During current production, CNC milling, or 3D printing, is used much later on in the development cycle to produce dedicated molds. However, for products in the early phase of development, less than five functional samples are usually made due to the high cost of carving with hot knives and time-consuming manual processes.

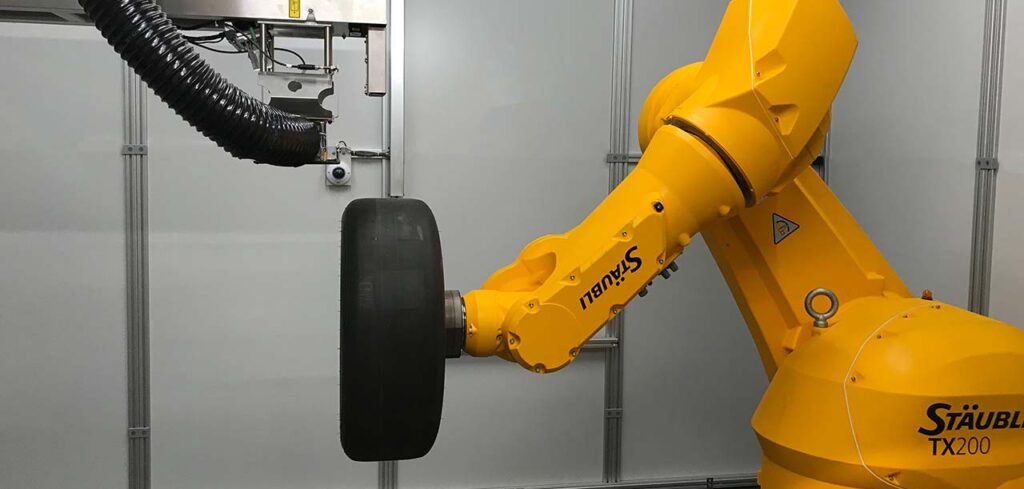

Featuring integrated JenSCAN Tire technology developed by Jenoptik, the new prototyping machines from 4JET enable both the tread and sidewalls of prospective tires to be machined true to size, almost entirely from CAD data. A pulsed laser is used to remove excess material from the tires surface with minimal heat impact, and requiring no post-processing. The companies claim the laser machines are capable of producing hundreds of prototypes a year to meet the needs of tire development facilities. Furthermore, optional upgrades can be added that enable QR codes and tracking information to be marked into prototypes.

Julio Javier Frank, vice president of sales at Jenoptik’s Light and Production Division, commented, “We are glad to have a strong partner at our side. Through this cooperation, Jenoptik’s Light and Production division gains access to key contacts and decision makers in the tire industry through 4JET’s existing network.

“In particular, we are involved in prototype production for the pre-development of future tires, where, for example, the development process for CO2 reduction and rolling resistance reduction, as well as other parameters, can be significantly accelerated. This partnership is a win-win situation for both our companies and complements 4JET’s range of laser applications”.