Having started tire recycling in 2005 with the construction of its Recycling Technology and Service Center, ZC Rubber has continued to incrementally improve its efforts to reuse and repurpose discarded materials and products.

In 2009, Zhongce Recycling Technology was established by ZC Rubber to further increase company sustainability and the company intends to build a production line this year capable of producing 7,500 tons of liquid recycled rubber per year. The liquid recycled rubber material can replace over 98% of the pollutant-prone processing aids, in addition to improving compound quality and increasing tire service life.

To improve the sustainability credentials of its tire supply chain, ZC Rubber has worked in partnership with several domestic and international research institutions to reduce the impact of tires throughout their service life. As a result, the manufacturer has now built a holistic recycling industrial value chain which consists of tire recycling, sorting, retreading, pyrolysis and more. To date, ZC Rubber has recycled 400,000 tons of end-of-life tires, which has resulted in cutting carbon emissions by 510,000 tons.

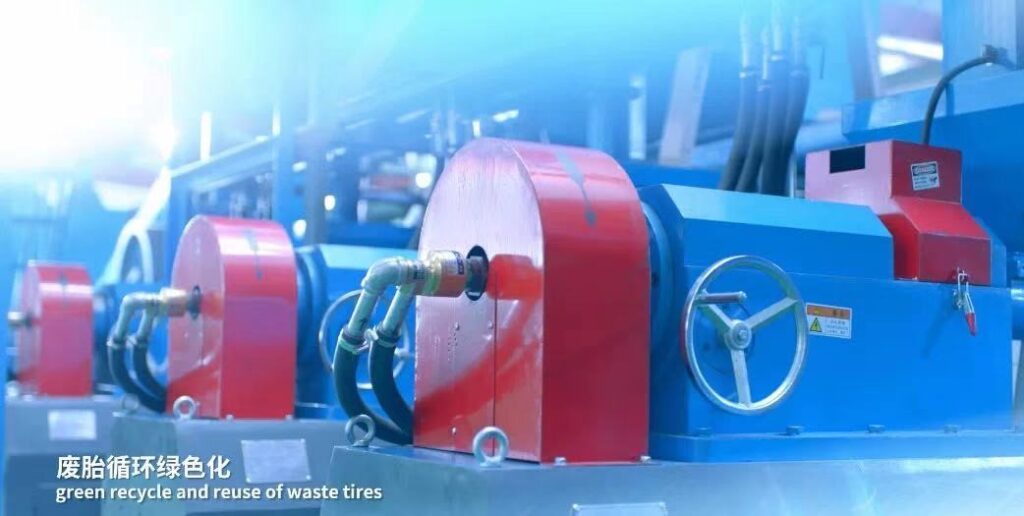

Through a collaboration with Nanjing Lvjinren Rubber & Plastic High-tech, the tire maker built an automatic reclaimed rubber production line with achieved a yearly production capacity of 20,000 tons of reclaimed rubber in 2020.

At Zhongce Recycling Technology, reclaimed rubber is prepared with no wastewater and zero emissions being produced because of modern machinery and the implementation of an internationally recognized process. Energy consumption per ton has also been reduced by over 20% compared to traditionally used methods.

Additionally, ZC Rubber is working in partnership with the Zhejiang University to develop a circular recycling supply chain. This will consist of converting end-of-life tires into high-quality raw materials including carbon black, pyrolysis oil, gas and steel.

The materials such as pyrolysis oil can be reused as a fuel oil for manufacturing carbon black. Once processed, the pyrolysis carbon black will be used as an alternative to regular carbon black. Zhongce Recycling Technology can recycle all rubber-based products internally for increased circularity. Furthermore, ZC Rubber plans to build a tire pyrolysis processing line with a 5,000-ton yearly capacity before the end of 2022.

“ZC Rubber is developing innovative solutions today to address economic, environmental and social development challenges,” said a ZC Rubber spokesperson. “To encourage a more sustainable future, we are making considerable investments in recycling technologies and smart production.”