The Beijing University of Chemical Technology, China, has announced the launch of a bio-based itaconate-butadiene material.

Led by Liqun Zhang, research for the project began in 2008 and after 13 years the team at the university says it has managed to develop a high performance and bio-based itaconate butadiene rubber.

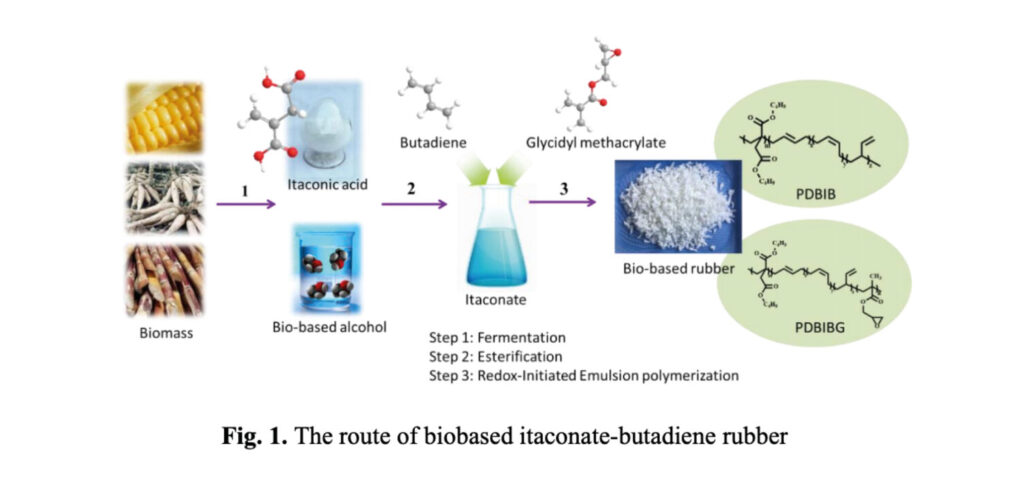

Epoxy group functionalized poly (dibutyl itaconate-co-butadiene-glycidyl methacrylate), or PDBIBG, is claimed to be the first class of macromolecular chain structures based on an itaconic acid resource, which it is hoped will allow for high utilization of biomass resources while promoting sustainable development of the rubber industry.

The comprehensive properties of the functionalized bio-based itaconate butadiene rubber obtained are said to be the same, if not better, than traditionally rubbers. It is estimated that the production of bio-based itaconate butadiene could reduce carbon emissions by 1.44 tons per ton of rubber produced.

Through a combination of molecular structural design and use of a non-petroleum-based silica, coupled with an in-situ process to tune the viscoelastic properties of the elastomer composites, silica/PDBIBG nanocomposite-based green tires should benefit from a low rolling resistance, excellent wet skid resistance and good wear resistance, improving fuel efficiency and reducing the dependence on petrochemical resources.

According to the researchers, the tires achieved a rolling resistance and wet skid resistance level B by the EU Tyre Labelling Regulation 1222/2009, including the first ever batch of functionalized bio-based itaconate-butadiene rubber radial tires.

The Beijing University of Chemical Technology, Shandong Chambroad Sinopoly New Material, Shandong Linglong Tire and the Goodyear Tire and Rubber Company have successfully established a 1,000-ton production line of PDBIBG materials in China, for the manufacture and testing of PDBIBG tires.