The conclusion of an agreement with Shell Eastern Petroleum (Shell) for the supply of butadiene derived from plastic waste and biomass (sustainable butadiene) has been announced by Japanese company Asahi Kasei.

By the end of fiscal 2021 in March 2022, Asahi Kasei aims to begin producing and marketing sustainable solution-polymerized styrene-butadiene rubber (S-SBR) using the sustainable butadiene at the company’s plant in Singapore.

S-SBR is a type of synthetic rubber and is utilized for the production of fuel-efficient, high-performance tires. As environmental regulations tighten, global demand for these eco-friendly tires is growing. With desirable characteristics and its ability to maintain safety performance, the material is well-suited for the production of eco-friendly tires.

Furthermore, with the tire sector working toward better fuel efficiency and increased wear resistance, the demand for more sustainable S-SBR is also increasing.

Asahi Kasei is to continue focusing on the development of high-performance S-SBR products that contribute to increasing fuel efficiency and wear resistance to meet the requirements of the mass production of electric vehicles with longer ranges.

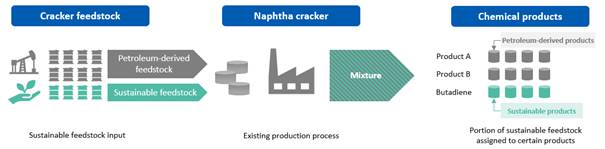

The company also seeks to transition to a sustainable feedstock to reduce CO2 emissions created by its supply chain. Shell is to produce sustainable butadiene by utilizing the mass balance method (see graph below) in two ways at its facility in Bukom, Singapore.

The first method will consist of converting plastic waste into pyrolysis oil and feeding it to the naphtha cracker, and the second method will involve using bio-feedstock as a naphtha cracker feed.

Asahi Kasei predicts that by utilizing sustainable S-SBR a significant reduction in CO2 emissions can be achieved over a tire’s lifecycle.