Yokohama has developed what is claimed to be the world’s first technology capable of efficiently producing isoprene from biomass. The breakthrough was achieved through joint research with Riken and Zeon Corporation.

Isoprene is a raw material used in the production of synthetic rubber (polyisoprene rubber) applied in tires and other applications. Industrial isoprene is currently produced as a by-product of naphtha pyrolysis. The development of this new technology for synthesizing isoprene will reduce dependence on petroleum and contribute to the reduction of CO2 in the environment.

Yokohama, Riken and Zeon jointly discovered through their research in 2013 and in 2015, a new isoprene-synthesizing process using a computer-based in-silico metabolic design technology.

Further development of this new technology has led to the creation of cells with excellent isoprene-synthesizing capability based on a new artificial pathway and highly active enzymes.

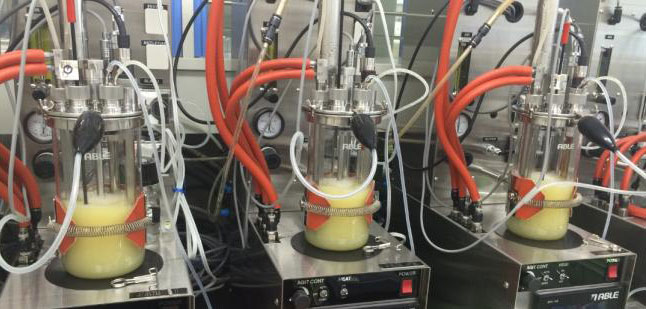

The technology has succeeded in creating cells with the in-vivo capability of generating isoprene from a biomass (sugar) that serves as the starting material.

The in-vivo generated isoprene is then polymerized to achieve synthesis of polyisoprene rubber. The research leveraged Riken Center for Sustainable Resource Science’s (CSRS) cell design and plant science technologies.

It is widely understood that isoprene is produced naturally from mevalonic acid (an intermediate substance formed from sugar) through a five-stage reaction, but the new artificial pathway constructed through the joint research reduces that process to two stages.

Furthermore, the highly active enzymes possess a phenomenal isoprene-producing capability that is not achievable by natural enzymes. Introducing this artificial pathway and these enzymes into colon bacilli gives the bacteria an isoprene-generating ability that it lacks in nature and enables an efficient artificial synthesis of isoprene. Yokohama has confirmed that this technology can also be applied to butadiene-based synthetic rubber and other diene rubbers.

Riken is Japan’s only comprehensive research institution for the natural sciences. Riken CSRS’s research focuses on biological functions, especially its basic research on the effective use of plant-microorganism bioprocesses. Zeon, a manufacturer of synthetic rubbers, places an emphasis on polymerization catalyst technology and enhancing the performance of synthetic rubbers.