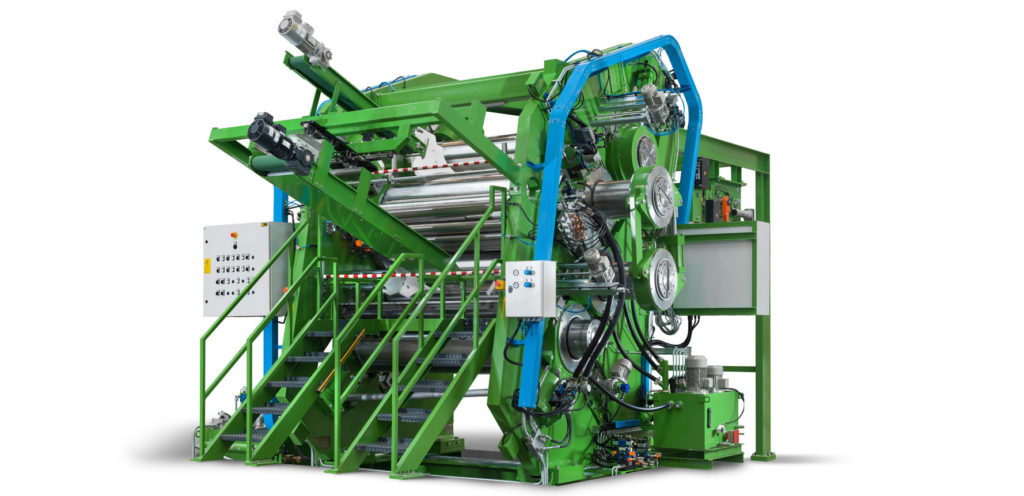

A major tire manufacturer has chosen Rodolfo Comerio to manufacture a unique calendering line for its new factory in India.

The system produces rubberized textile cord and innerliner, and can also be rearranged for future manufacturing of rubberized steel cord. Such an innovation will enable the tire maker to maximize its profits and ultimately get the best return on investment. This ‘super-combined’ calendering line will be manufactured at Rodolfo Comerio’s facilities in Solbiate Olona in Italy.

The super-combined calendering line will be able to exceed daily productivity levels of 370 tons and will be used to produce material for all types of tires, from giant tires for agricultural applications to passenger car tires, and two- and three-wheel vehicle tires.

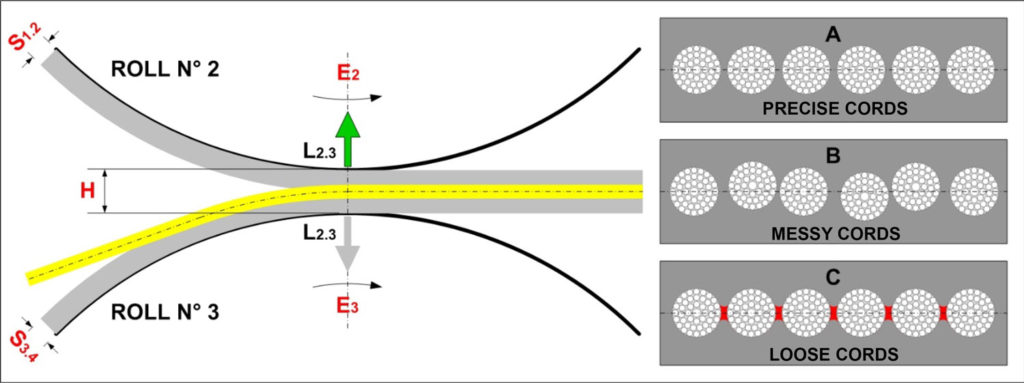

Inventions developed by the supplier for its latest generation of calenders include its RC SF-FreeSystem friction-free roll shifting. This technology brings numerous improvements in the calendered material – it enables an improvements in the rubber penetration into the textile or steel cord; better thickness accuracy; improvement of the cords distribution end-count per inch (EPI or EPD); and the possibility to reduce the thickness.

New technologies adopted in the pre- and post-calender sections significantly increase productivity and enhance safety for operators; thanks to the increase in automation, the amount of manual interventions needed has been greatly reduced.

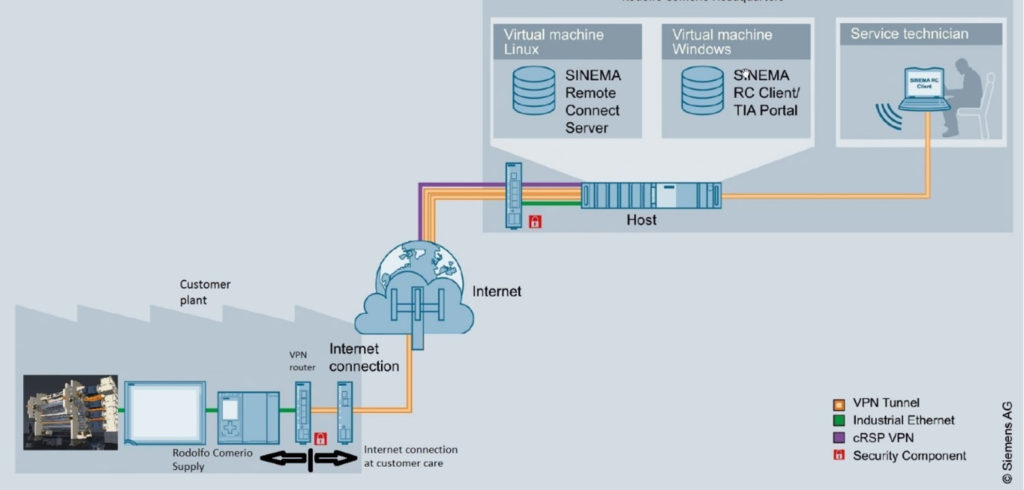

The company has also introduced new assistance plans to ensure even faster installation and startup of the plant.