Identec Solutions has been awarded the contract to supply its real-time localization system to 20 of one of the largest tire manufacturer’s factories worldwide.

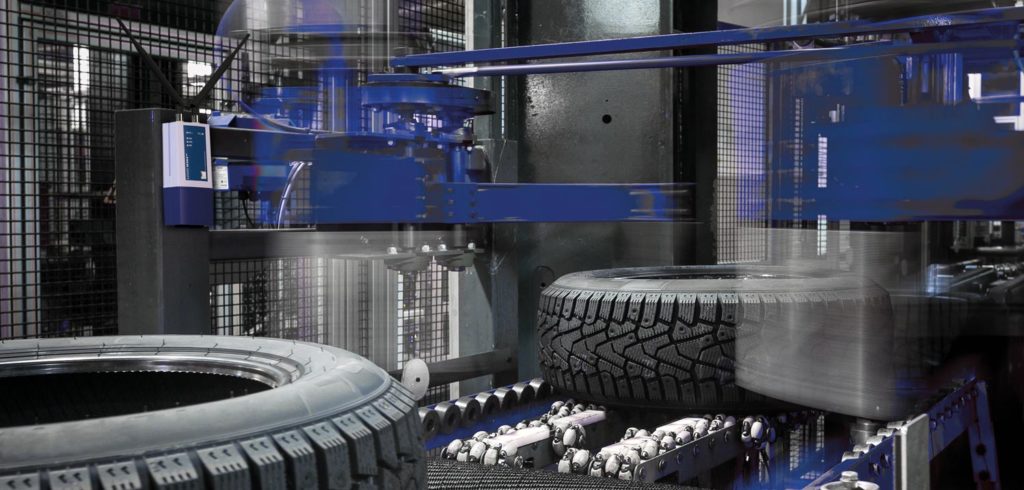

The localization and identification system from Identec Solutions has already been installed at an international tire manufacturer’s facility in 2016. It enables increased product quality while automating production processes at the same time. The system also prevents manual data collection ensuring error-free and efficient flow of material in production. To achieve this, all semi-finished products are automatically localized at the manufacturing station, identified and checked for accuracy. The localization data is transmitted in real time to the production and merchandise management system – enabling an automated and digitized production process.

More than 60,000 material carriers and trolleys for semi-finished products are equipped with an innovative transponder, plus over 1,800 processing machines with corresponding collection devices. In addition to the localization function and automatic identification, the solution supplied by Identec Solutions also has a “pick by light” function. With this function the material carriers and trolleys can be visually localized at any spot in the production facility via light signals. In so doing, time-consuming and resource-intensive manual search processes are eliminated.

The fully automated merchandise localization minimizes potential sources of errors, which can occur through manual systems such as barcode scanners, and replaces them completely. The processes become more efficient and virtually error-free. Furthermore, production management receives consistent real-time information about the current status of production and merchandise flow.

March 6, 2018