Sumitomo Rubber Industries (SRI) has been working with Professor Hiroshi Tani of Kansai University, Japan, on the joint development of an innovative power generating device – or ‘energy harvester’ – which harnesses the rotation of a tire to generate electricity, which can then be used to provide power for peripheral sensors installed in and around the tire, eliminating the need to rely on batteries. The tire maker has now succeeded in developing techniques for measuring tire wear status and contact footprint utilizing these energy harvesters.

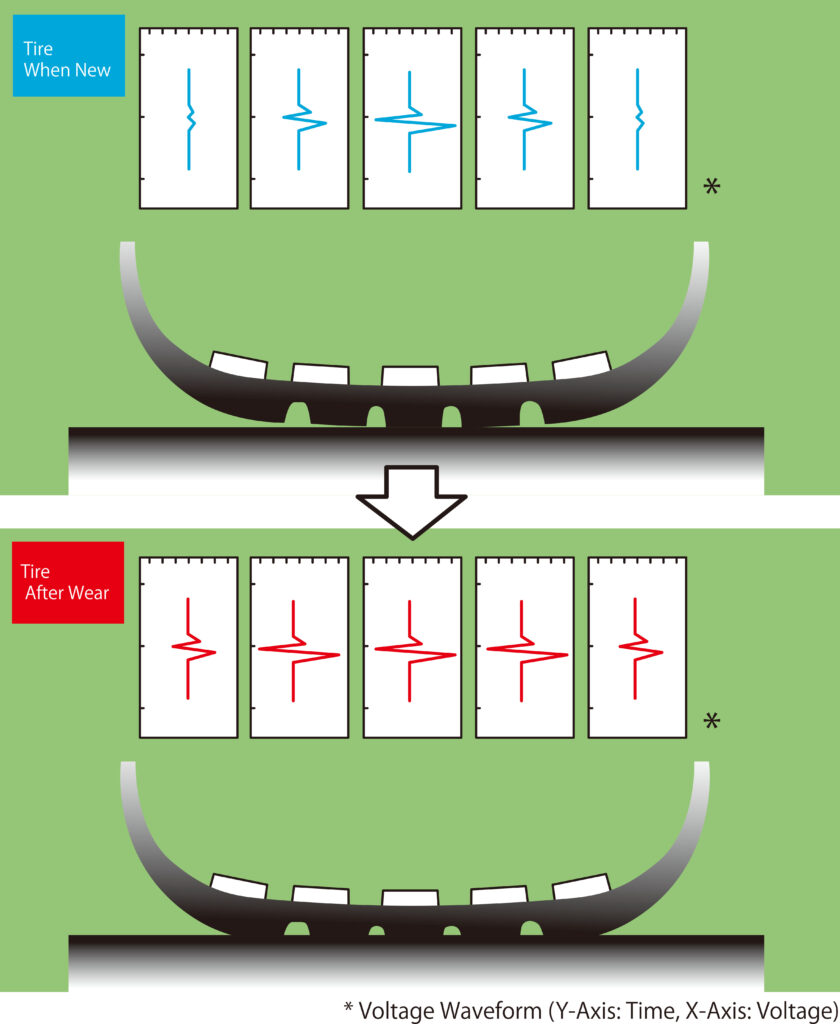

This latest advancement makes it possible to calculate tire footprint length and rotation cycle in addition to device voltage levels, based on voltage waveform data obtained from each energy harvester as tires rotate while in contact with the road. The results of these calculations can then be extrapolated to estimate tire wear levels.

SRI has also developed a technique for measuring a tire’s contact footprint, which involves installing multiple miniaturized energy harvesters within each tire to obtain data on the contact footprint in the direction of width. In addition to enabling various applications for tire solutions services, these new technologies will provide valuable data which can be used in future tire development.