Sumitomo Rubber Industries has developed a new system of analysis utilizing artificial intelligence which will ultimately enable improved tire performance and slower wear rates.

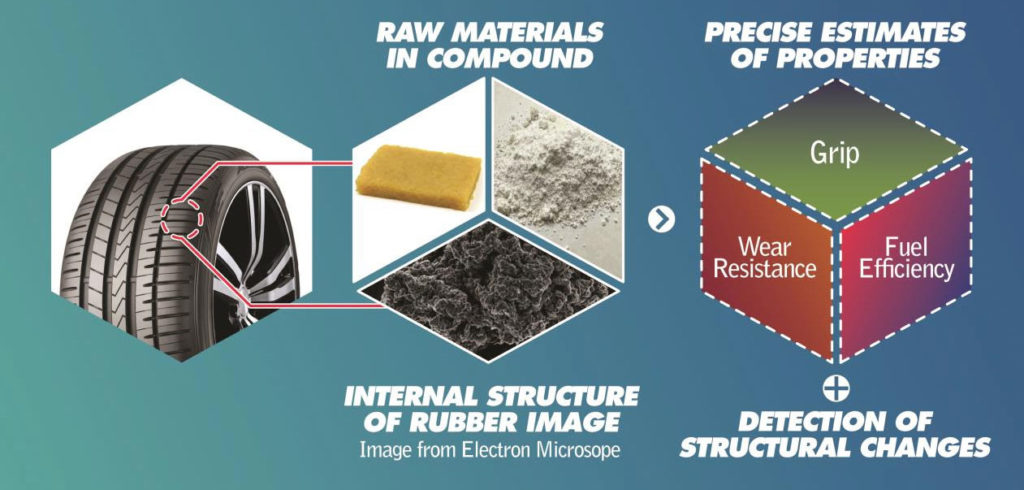

Tyre Leap AI Analysis was developed by SRI in conjunction with Professor Miki Haseyama at Hokkaido University. It uses real-world data and image processing techniques such as electron microscopy to analyze and compare new and old tires. Gathering this data means precise predictions can be made of how changes in compounds affect tire performance throughout the tire’s life, with the potential benefits of improved wear rates and more consistent performance across the tire’s lifespan. As well as increasing safety, the use of this analysis has the potential to increase the service life too.

Dr Bernd Lowenhaupt, managing director of SRI Europe, commented, “Our new Tyre Leap AI Analysis technology is capable of dissecting compounded rubber, which comprises of a range of materials including natural/synthetic rubber polymers, carbon black or silica-based reinforcing agents, cross-linking agents and additives. It can then evaluate the multiple ‘interlocking’ factors that relate to the materials and the structures they form. It’s another element of our Smart Tyre program, for the development of a tire that delivers better performance for longer.”