With a strong focus on sustainability and innovation, Tire Technology Expo 2024 is shaping up to be one of the biggest and best yet. Held on March 19, 20 and 21, 2024, at the Deutsche Messe in Hannover, Germany, the show includes a superb line-up of exhibitors, conference topics and speakers, as well as a range of accredited short courses, the official Tire Technology International Awards for Innovation and Excellence, and ample opportunity for peer-to-peer networking. Register for your free fast-track exhibition entry pass here.

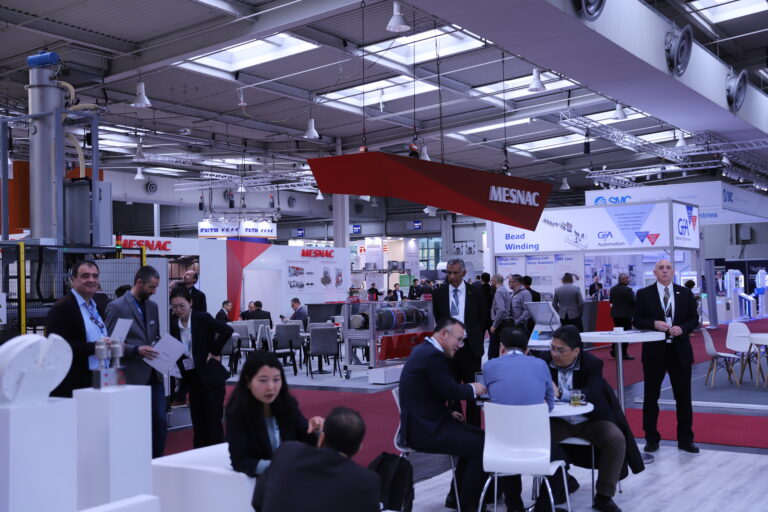

The exhibition

The industry’s premier technology showcase, the free-to-attend exhibition features all the latest equipment and materials from more than 240 specialist suppliers, covering the complete spectrum of the tire manufacturing process.

Early exhibitor highlights include the latest in 3D laser surface texturing, AI, elastomer characterization systems, natural rubber, green tire technology, carbon black, RFID, tracking and identification labeling, and in-line quality measurement systems.

For example, Zeppelin Systems, which provides solutions for the mixing room and beyond, will exhibit its latest developments in silo storage, pneumatic conveying, weighing and feeding of powders, chemicals, solids and liquids, as well as its recycling technologies along the entire supply chain.

Kuraray will showcase its silane-modified liquid butadiene rubber (GS-L-BR), a new series of liquid rubbers tailored for the EV market. The silane-modified liquid butadiene rubber incorporates a reactive silane group that greatly enhances interaction with silica fillers and natural rubber (NR) in tires, which is crucial for EV applications. This synergy yields improvements in tire grip, rolling resistance and abrasion resistance, leading to an extended tire lifespan and superior driving dynamics.

Kuraray will showcase its silane-modified liquid butadiene rubber (GS-L-BR), a new series of liquid rubbers tailored for the EV market. The silane-modified liquid butadiene rubber incorporates a reactive silane group that greatly enhances interaction with silica fillers and natural rubber (NR) in tires, which is crucial for EV applications. This synergy yields improvements in tire grip, rolling resistance and abrasion resistance, leading to an extended tire lifespan and superior driving dynamics.

Cheeshine will explain how it has developed a more sustainable bio-based plasticizer using a series of modified cashew oil and soybean oil (non-food chain) with high biomass content and free from PAHs, as an alternative to the large consumption of petrochemical base raw materials. The company states that its solution improves the processing property, has excellent low-temperature performance, good plasticizing effect, excellent physical property and low rolling resistance.

NTE Process will present its dense-phase pneumatic conveying systems that are equipped with its patented Air Assist technology and are ideal for primary products for tire production, ensuring the integrity of carbon black and silica (fines <1%). Suitable for low-speed transportation systems (<5m/s) and long distances (over 150m), Air Assist uses artificial intelligence to increase system efficiency up to 40%, while reducing energy consumption by up to 70%.

NTE Process will present its dense-phase pneumatic conveying systems that are equipped with its patented Air Assist technology and are ideal for primary products for tire production, ensuring the integrity of carbon black and silica (fines <1%). Suitable for low-speed transportation systems (<5m/s) and long distances (over 150m), Air Assist uses artificial intelligence to increase system efficiency up to 40%, while reducing energy consumption by up to 70%.

ZF Test Systems will present its Tire Efficiency Tester (TET) – a new tire test bench with the main task of determining the energy efficiency and rolling resistance of a tire. The TET not only tests tires for efficiency, but it is also highly efficient itself. The use of electric drives eliminates the need for hydraulics, thus reducing energy requirements and maintenance. Braking energy is fed back into the system through recuperation. An important application of this machine will be safeguarding the label value ensuring adherence to stated specifications in tire production.

ZF Test Systems will present its Tire Efficiency Tester (TET) – a new tire test bench with the main task of determining the energy efficiency and rolling resistance of a tire. The TET not only tests tires for efficiency, but it is also highly efficient itself. The use of electric drives eliminates the need for hydraulics, thus reducing energy requirements and maintenance. Braking energy is fed back into the system through recuperation. An important application of this machine will be safeguarding the label value ensuring adherence to stated specifications in tire production.

The awards

Key industry achievements will also be recognized at the event, during a live presentation of the Tire Technology International Awards for Innovation and Excellence. The awards are decided by the votes of a panel of experts from the tire industry and academia. The winners will be announced during the Expo.

The 2023 awards saw the debut of a host of new categories – which enable the awards to recognize and reward an even greater selection of worthy winners, and will remain in place for the 2024 awards. The full shortlist is available here.

The conference

Bringing together leading industry figures, the Tire Technology Expo Conference will consist of three days of presentations, discussions and networking on the latest developments in tire manufacturing, scientific advances, sustainability and the global tire business.

The conference will feature more than 180 expert speakers from leading companies and institutions, such as Michelin, Apollo Tyres, Sumitomo Rubber Industries, GDSO, Kumho Tire, Jaguar Land Rover, University of Twente and many more, including the European Commission.

Leading speakers include: Li Yanguo, compound and material research, Linglong Tire; Guy Heywood, vice president, Hankook Tire Europe; Mohammad Behroozi, vehicle dynamicist, GM; Tetsuya Maeakwa, manager – material planning, Sumitomo Rubber Industries; Jan Prins, technical group leader for wheel and tire development and modeling, JLR; and Dalia Broggi, project manager, scientific research, European Commission.

With new topics and streams announced for 2024, the conference is set to bring more insight than ever. In addition to its regular content, speakers will discuss AI applications in tire R&D and manufacturing, intelligent connected tires, sensors and data acquisition, sustainable tire manufacturing, the circular economy and mitigating TRWP. This year there will be more than 40 presentations on simulation, modeling and test and development alone – view presentation highlights here.

Short courses

Three short courses will be held concurrently with the exhibition and conference.

The University of Akron Tire Mechanics is a four-day short course held on March 18, 19, 20 & 21, 2024. Starting the day before the exhibition opens, it will provide engineers and scientists with an in-depth, intense study of the latest developments surrounding tire engineering. The basic and practical aspects of the mechanics of pneumatic tires will be introduced by internationally renowned experts in tire mechanics, and those who complete this course will receive a certificate from the University of Akron.

The Tire Modeling and its Application in Tire and Vehicle Development three-day short course (March 18-20) which will be organized and co-presented by Mohammad Behroozi from GM. The course covers the computer modeling of tires in a full vehicle system and is aimed at engineers and researchers working in industry or academia. The subject matter will be of primary interest to vehicle dynamics engineers, for whom the tire is the primary force and moment generation element on the vehicle. It is also useful for engineering managers who wish to understand existing tire modeling activity and its challenges, or to successfully implement new tire simulation processes in the workplace.

The 10th Tire Reinforcement Materials, Applications and Fatigue Testing one-day short course (March 18), will provide an understanding of the use of materials and constructions for rubber reinforcement in the tire. This course is intended for tire reinforcement engineers from design and material laboratory departments of tire manufacturers and their reinforcement suppliers.

Please visit www.tiretechnology-expo.com for the full exhibitor list, conference program and short courses schedule, and to register for your free exhibition entry pass. You can read Tire Technology International’s full show preview, here.