In a recent interview ahead of Tire Technology Expo, March (18,) 19, 20 and 21, 2024, Michelin’s initiative leader for connected offers, Hélène Bathias, and Jérémy Vayssettes, development program leader for connected mobility, discuss the company’s algorithms for tire predictive maintenance solutions, at a time when vehicles are becoming more connected and EV numbers are increasing.

What is your presentation about?

To provide services that satisfy car makers’ expectations, Michelin is developing a complete offer around algorithms based on vehicle data. In this presentation, we will focus on algorithms for tire predictive maintenance and related use cases focused on car makers’ needs. The algorithms developed by Michelin are sensorless, brand agnostic and easy to deploy. We will illustrate why Michelin has chosen this approach and what the benefits are for customers.

How important is tire predictive maintenance?

With the growth of electric vehicles, this subject has become especially important. Tires are becoming the first item needing maintenance on electric vehicles as less maintenance is needed on other elements and tires wear faster on EVs than ICEs: an electric vehicle that is 20% heavier than its ICE equivalent would wear its tires 20% faster.

Tire change will therefore be a key point of contact for car dealers and drivers. On top of this, tire impact on vehicle performance is far more visible in electric cars, because drivers can more easily detect a decrease in range when changing for a tire with a higher rolling resistance – in an ICE, the impact on fuel consumption is not immediately obvious – and tire noise is an EV-specific annoyance because it is not masked by the noise of the engine.

On top of that, monitoring tire wear enables drivers to change the tires at the right time. In our last study, 50% of drivers changed their tires before 3mm, meaning they lose 25% of tire lifespan if we consider that a new tire is 7mm. We aim to make tires last longer and save materials and CO2, which is good for the planet and the driver’s budget.

For fleets, monitoring the tires and planning changes is mainly a matter of cost savings and driver safety.

How do Michelin’s algorithms predict a tire’s end of life?

How do Michelin’s algorithms predict a tire’s end of life?

Tire end of life is mainly related to two things: wear and pressure. Michelin leverages its knowledge in tire physics to provide accurate, reliable, and easy to deploy solutions using only data coming from existing sensors in the vehicle. These solutions are the result of mixing AI and physical models as well as sophisticated data fusion methods.

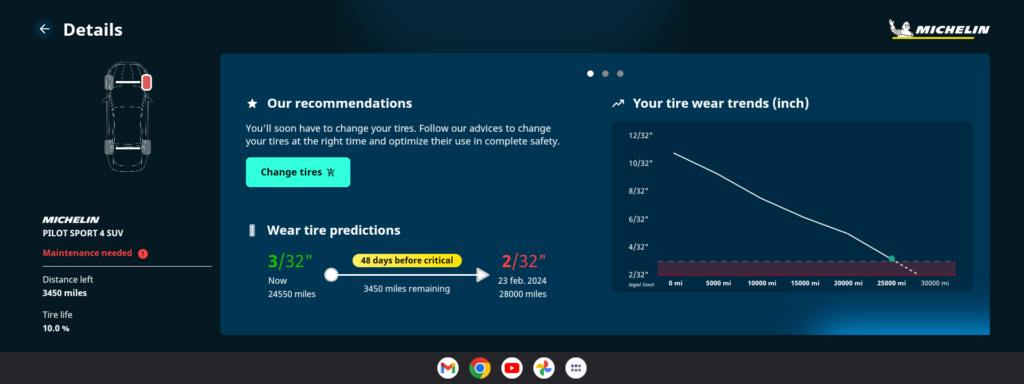

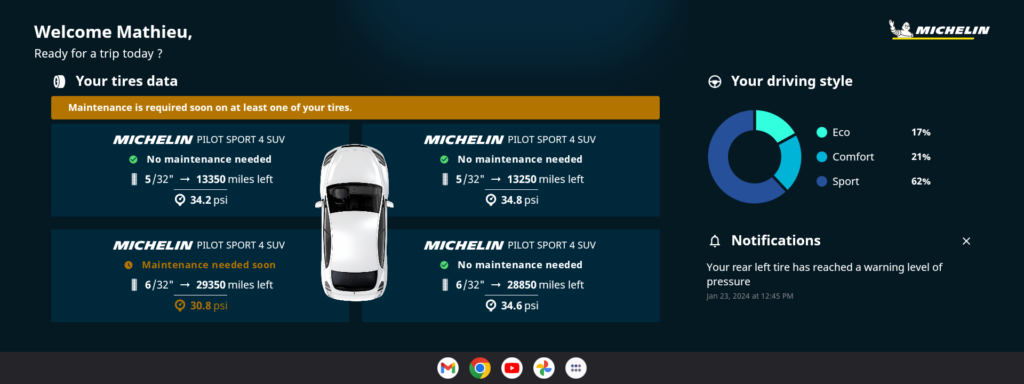

For the wear part, we call our solution Michelin SmartWear. Its aim is to predict the lowest tread depth point on the tread pattern of each tire. It behaves as a physical tread depth gauge: as soon as the vehicle is driving, the algorithm computes the vehicle signals at a high frequency and deducts a tire tread depth measurement estimation. You then have a continuous wear level monitoring of your tires. The algorithm also formulates the end-of-life prediction based on wear trend analysis.

Regarding pressure loss and punctures, our Michelin SmartLeak algorithm detects slow leaks at an early stage and can predict when the critical limit will be reached, thanks to TPMS data.

Which algorithms for predictive tire maintenance and related use cases will be explored?

We aim to answer the main pains regarding tire end of life today, to make tire management as seamless as possible: as a driver, when do I have to change my tires? It seems easy, but today most drivers are changing their tires too soon, which is neither good for their budget nor the planet. With the Michelin SmartWear algorithm and its accuracy, you can have an objective measure and advice. But the next question is: what tire do I have to choose? Knowing your usage, Michelin can use its tire expertise to support you on tire type choices with objective information, highlighting their impact on vehicle performance. If needed, with the support of our dealer networks, we can also help on the last question: where can I find my tires?

Another use case would be having a tire puncture with a slow leak. With Michelin SmartLeak, we can detect upfront any pressure loss and predict when it will be necessary to stop: is it a question of minutes (fast leak), hours or days? We can then give the right advice on where to repair or refill the tire.

How are the algorithms sensorless, brand agnostic and easy to deploy?

The solutions we propose to car makers today are software based, with algorithms and over-the-air updates for any kind of tire. We have developed our algorithms based on existing signals in the vehicle, so we do not need extra sensors in the vehicle or the tire for these use cases, which would add complexity.

For car makers, it would make no sense to only be able to monitor Michelin tires; our knowledge about tires allow us to monitor any tire brand. But what is even more important is being sufficiently flexible to integrate this software in different vehicle architectures and offer a turnkey solution to car makers. For example, we have a partnership with BlackBerry IVY to pre-integrate our software in their in-vehicle software platform, to optimize integration costs and provide update capabilities.

Finally, our solution requires only a quick learning phase prior to integration.

What are the advantages of the Michelin approach in comparison to other state-of-the-art approaches; how accurate are the algorithms?

What are the advantages of the Michelin approach in comparison to other state-of-the-art approaches; how accurate are the algorithms?

The challenge from the engineering teams was to have a product that was accurate, of course, but also able to handle all kinds and brands of tires, and all kinds of use cases on the market, without adding sensors in the tire or in the vehicle and without any personal data.

Thanks to our physical approach, we can handle a lot of current use cases, especially tire changes for summer/winter. For instance, as we do not need to know the tread depth starting point, the algorithm can monitor the half-worn tires that you just put on your car for the second winter season.

Regarding tire wear monitoring, the accuracy we commit to is +/-1mm, wherever the vehicle is driving. Testing has proven that we are far more accurate in most cases.

Why did you choose to speak on this topic at Tire Technology Expo and why is it important at this time?

We are at a crucial point for the automotive industry, where technical capacity can answer social needs: vehicles are connected, enabling updates and more and more electrics. Drivers are searching for a seamless experience, transparency and more eco-friendly solutions.

We choose to speak about this today because we are ready, both in terms of algorithm maturity and integration capacity. We hope to do our bit.

What takeaways can the audience expect?

We have an existing software solution regarding tire predictive maintenance for car manufacturers that is easy to deploy and that offers multiple benefits for car makers, car dealers and racing drivers.

Hear from Hélène Bathias and Jérémy Vayssettes on Wednesday, March 20. View the conference program at Tire Technology Expo 2024.