Yokohama Rubber Co. has revealed another strand of its rubber development technology based on materials informatics – expected to dramatically improve the accuracy and speed of the development of high-performance rubber materials.

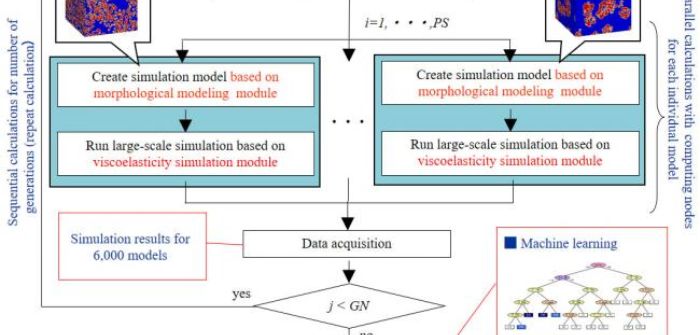

It combines the simulation technology that emerged from the company’s research aimed at fostering new ways of thinking about rubber material design, with data generated by its research on the design, processing, analysis and measurement of existing rubber materials. It also incorporates information and knowledge exploration using AI (machine learning).

The new technology’s use of AI to search through the vast amount of data from numerous simulation results (design factors and characteristic value data) makes it possible to derive the morphological design factors critical to achieving the desired performance and the related thresholds (limitation values) in a short period of time with a high degree of objectivity and quantitative accuracy.

In addition, by using the design and processing parameters of existing rubber materials and the results obtained from analysis and measurement of those materials, the new technology greatly improves the precision of material searches and thus reduces prototyping man-hours required by material development.

In addition, the use of a new simulation technique (coarse-grained molecular dynamics simulations) makes it possible to analyze the mechanism by which the various design factors impact mechanical properties, which could lead to new development approaches in the future.

Using this new technology to simulate a rubber material that could combine rolling resistance with high wear resistance, Yokohama Rubber found that a filler radius smaller than the certain threshold value combined with a thinner than certain bound rubber layer formed on the filler’s surface delivered the desired result.

In addition, coarse-grained molecular dynamics simulations unveiled the mechanism by which a smaller filler radius increased rigidity while a thinner bound rubber layer reduced energy loss.

Materials informatics’ use of information science, such as AI, makes it an effective means for searching for new materials and substitute materials, and for estimating the performance of these new and unfamiliar materials.

Material searches to date have relied on researchers’ experience and intuition; the new technology will facilitate speedier discovery of new materials with the desired characteristics.

November 14, 2017