The key feature of Yokohama’s new technology is its use of artificial intelligence (machine learning) to conduct information and knowledge searches, which are expected to greatly increase the speed and precision of new high-performance tires development.

The process is an advanced version of simulation technologies previously developed and applied by the company to create new products, such as the technology developed in 2015 for multi-objective design exploration of rubber materials that has enabled it to create models of a huge number of virtual rubber material morphologies.

In addition to shortening the time required to run such searches, the use of AI leads to a more objective and quantitative analysis of the factors that will contribute to a tire design with a balanced array of performance attributes suitable for various product categories.

For example, when developing a tire that delivers high performance in two areas normally thought to work against each other, such as fuel efficiency and abrasion resistance, Yokohama used the new technology during the rubber material design stage (materials informatics) to determine the optimal range of values for the size of the compound filler and the thickness of the bound rubber layer formed on the filler surface.

Similarly, the technology contributes to the design of tire shapes by generating the optimal size for the radius of the curvature of the tire’s cross-section.

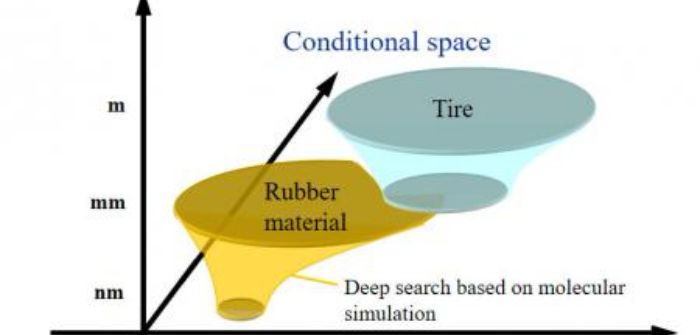

The new technology also makes it possible to acquire data from a vast design space that far exceeds the scope of previous studies. This will enable researchers to obtain new design factors that lead to new breakthroughs.

They also will be able to analyze the mechanisms important to each design factor, which will help them come up with new development approaches based on those mechanisms.

November 1, 2017