Toyo has developed a new device that effectively reduces resonance in tire cavities, which is one of the main sources of interior noise.

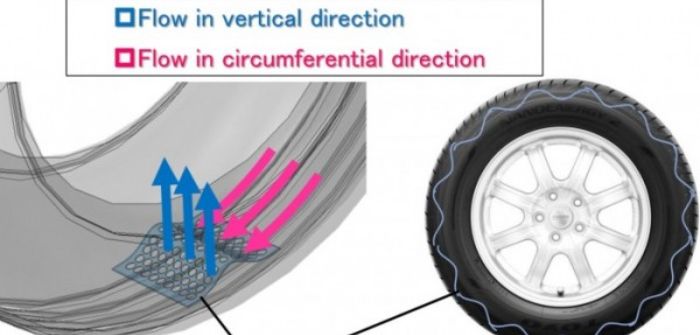

Engineers conducted simulations to visualize the air inside the tire when the tire is rolling. It was ascertained that the air itself generated flow in the circumferential direction and in the vertical direction.

One method for reducing tire cavity noise is to mount sound absorbing material internally. However, Toyo engineers turned their focus to the air flow inside the tires.

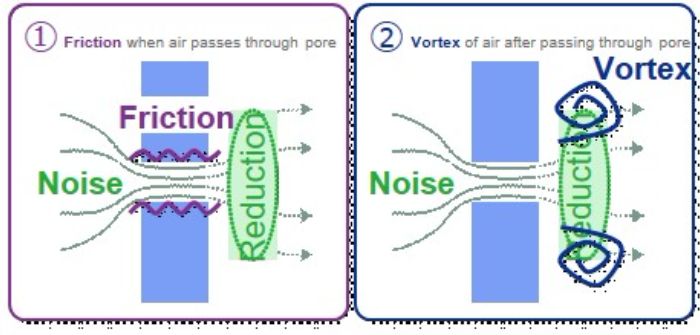

Noise is reduced when it passes through a pore. There are two attenuation mechanisms, namely, friction generated at the wall faces of the pore that the air passes through, and a vortex that is generated by the sound passing through the pore.

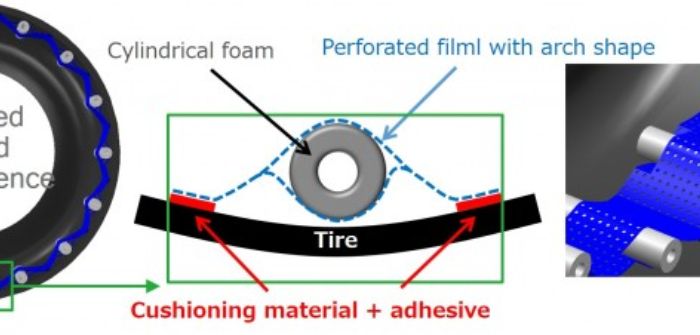

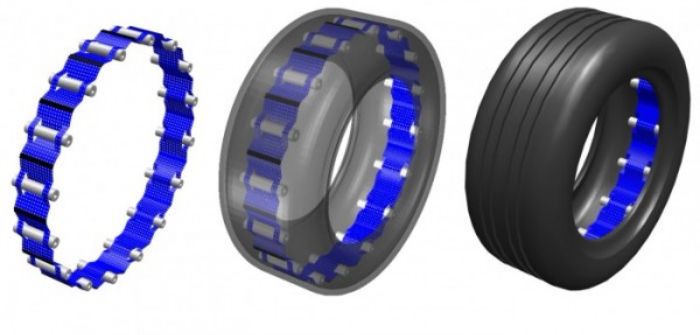

A specially developed porous film is used to cover the air flow. In order to handle the flows in both the vertical and circumferential directions, a perforated film in an arch shape is used.

Cylindrical foam is also arranged at 16 base points around the tire’s circumference to hold the devices. The hollow structure of the cylindrical foam has a sound-attenuation effect, which works in synergy with the perforated film to further reduce noise.

Cylindrical foam is also arranged at 16 base points around the tire’s circumference to hold the devices. The hollow structure of the cylindrical foam has a sound-attenuation effect, which works in synergy with the perforated film to further reduce noise.

The audible range for humans is said to be approximately 20Hz to 20,000Hz. Tire cavity noise is in the frequency band of 200Hz to 250Hz. To check the efficacy of this device in reducing noise in this frequency band, Toyo engineers conducted a series of real-world tests.

The results of measurements taken inside the vehicle showed that tire cavity noise was notably reduced to a maximum level of -12dB in the frequency range of 200Hz to 250Hz, compared to tires that do not have this device installed.

The results of measurements taken inside the vehicle showed that tire cavity noise was notably reduced to a maximum level of -12dB in the frequency range of 200Hz to 250Hz, compared to tires that do not have this device installed.

Toyo plans to introduce the device in future products.