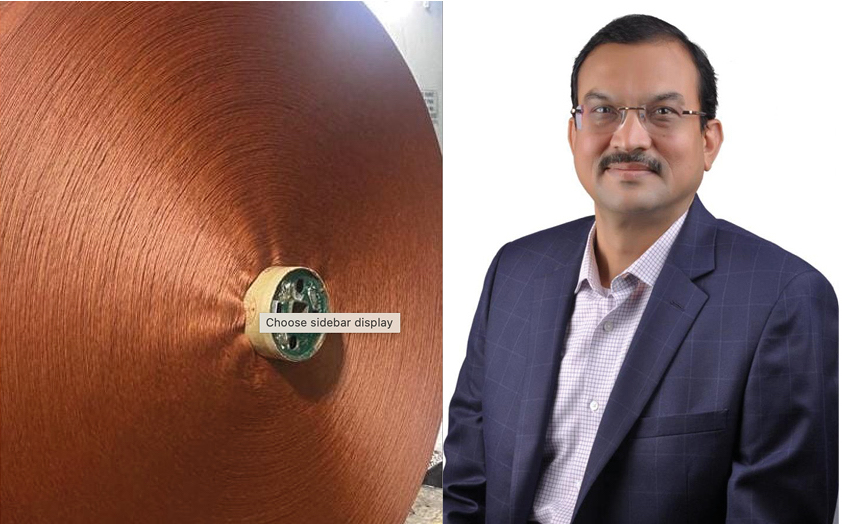

TTI speaks with Suresh Sodani, managing director and CEO of Century Enka, about the company’s recently developed nylon tire cord fabric (NTCF) made from 100% recycled nylon waste – a sustainable development which was nominated for this year’s Tire Technology International Awards for Innovation and Excellence.

Can you give us a little more detail on how and when the nylon tire cord fabric project began? How long has Century Enka been working on this?

Century Enka started working on sustainable nylon in 2015. The company has the technology to recycle in-house process waste and convert it into caprolactam – we inherited it from our technology partner Akzo, in the Netherlands. Century Enka ventured into making Nylon 6 polymers from recycled caprolactam, and this was used for making yarns for apparel and other applications. We established a robust supply chain with our partners in the USA for applications such as carpet, garments, shoes, bags and others for Europe and the US market. In 2019, we undertook a project with Apollo Tyres to make sustainable tire cord fabric for tire applications. It took us over two years to establish the quality norms before initiating commercial supplies to tire industry.

Why is it important to look for more sustainable solutions for use in the tire manufacturing business?

The automobile industry is one of the main sources of carbon generation. Efforts are being made consistently by auto manufacturers to shift to EVs, and to encourage the use of sustainable material in the making of two- and three-wheel vehicles, passenger cars, buses, and so on. Hence, every member of the supply chain must seriously investigate all areas of their manufacturing where sustainability can be introduced. The number of tires consumed over the life cycle of an automobile is huge, and any effort in making tires more sustainable helps in making the entire transport sector greener.

How important is it to work with tire makers, in partnership, to develop solutions and create a more circular economy?

Nylon tire cord fabric is used as reinforcement in tires. We certainly need strong support from tire companies to develop sustainable fabric for these applications. Each tire company has different specifications, and each product needs to be made as per their requirements. Currently, reprocessed nylon tire cord fabric is more cost intensive compared to virgin material. Tire companies would need to sell such green tires in a separate category and promote their green features suitably.

How did it feel to be shortlisted for the Materials Innovation of the Year category at this year’s Tire Technology International Awards for Innovation and Excellence?

How did it feel to be shortlisted for the Materials Innovation of the Year category at this year’s Tire Technology International Awards for Innovation and Excellence?

It was a pleasant surprise for Century Enka to get nominated for the award at this year’s Tire Technology Expo. An Indian company making bold statements in sustainability, and being the first one to do so in the world, is a great honor. The nomination gave us the desired acknowledgement of our efforts.

Does this recognize the hard work of you and your teams in developing these kinds of sustainable solutions?

Yes, it indeed recognizes the hard work which the team at Century Enka is undertaking in the field of sustainability. We would like to extend our efforts to all the companies across the globe. The idea is that a large number of bias tires should be made from sustainable reinforcement materials to reduce the use of crude oil and reduce carbon emissions in the intermittent process.

Can you tell us anything about future plans for more materials developments?

Century Enka has definite plans in CY 23, where we will be adding different attributes for sustainable NTCF and make it a special product for low rolling resistance. We have three or four concrete projects in hand which are exclusive in nature, and are being worked on with our strategic partners. Hopefully Century Enka will be able to publish the same before Tire Technology Expo 2024 in Hannover.