Where is isoprene traditionally sourced?

The current isoprene is made as a by-product of naphtha and is not a sustainable material, since naphtha is a fossil fuel. The new method, in which sugar is derived from a plant, is sustainable.

Why have scientists previously failed to produce isoprene from a biomass source?

Protein mutation technology has improved, and enzyme modification has become easier; I was able to produce a more active enzyme. We could use the existing method although it is not efficient and uses a lot of energy. The new technology is efficient because isoprene is synthesized in only two steps.

The two-step generation was realized because we were able to accumulate the stuck data of plant metabolic reaction and calculate the production route.

How easy was it to do?

Biotechnology continues to improve, as computational science database construction also progresses. In the future, as technology further advances, it can evolve further.

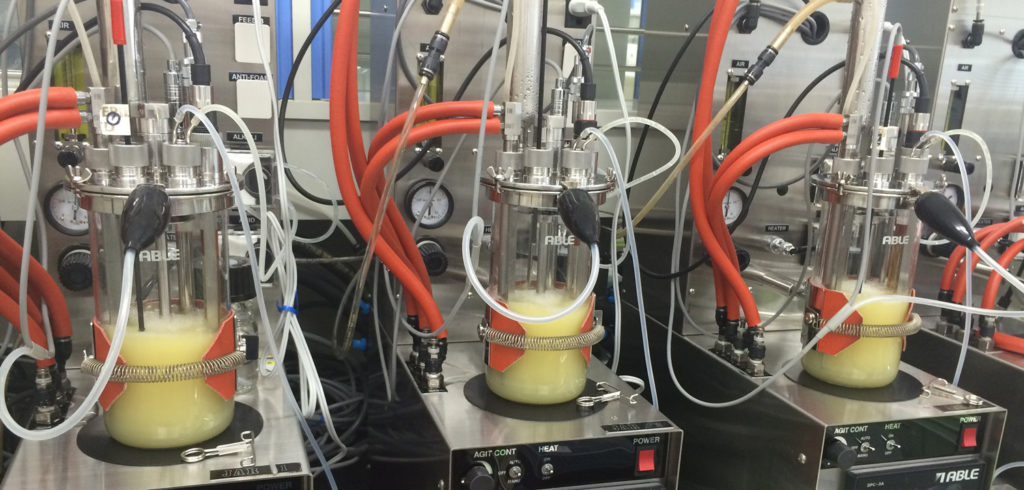

As it is already made in a fermenter, mass production will be possible. In fact, isobutene can be used in a similar way. It is mass-produced. The challenge is the costs. In order to compete with existing isoprene, the cost must be brought down.

Along with the practical application of shale gas, naphtha cracking, and the decrease in production volume, there is also a concern that the amount of the synthetic rubber monomer decreases. In this case, since the cost of existing products is increasing, in the near future, costs will no longer be as much of an issue.

What are the next steps for the work?

As cost is a problem, we need to develop the technology to make it cheaper. Ultimately, we need to develop a technology to produce rubber entirely from plants.

More on the technology here.