Ahead of his presentation at Tire Technology Expo 2024 in Hannover, Germany, Tetsuya Maeakwa, manager of the material planning department at Sumitomo Rubber Industries, discusses Active Tread, the company’s innovative concept for future mobility.

What is your presentation about?

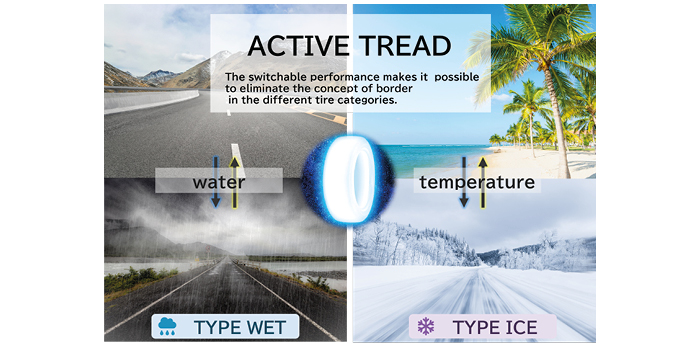

My presentation will focus on Active Tread, which is Sumitomo’s innovative concept for the future mobile society. SRI is launching the first Active Tread product line, which is a new technology for autonomous vehicles that promotes the establishment of a sustainable society. SRI will help to establish safety in the autonomous vehicle society by using Active Tread compounds. These enable the physical properties to actively switch to the optimized state in all weather conditions. The switchable performance makes it possible to eliminate the concept of border in the different tire categories.

What is Active Tread technology?

This is an unprecedented technology, that enables the physical properties of rubber to adapt to changes in road conditions, such as wet conditions. The technology is necessary to realize safety by changing the grip performance of the tire tread.

In general, grip performance in wet conditions is lower than in dry conditions. However, the Active Tread technology makes it possible for the physical properties of the tread compound to change to increase the grip force to its equivalent in dry conditions.

We have engineered the tire’s wet grip performance to be equivalent to dry conditions by adapting the mechanical properties of the tread compound with the Active Tire technology.

Why was the technology created specifically for autonomous vehicles? What benefits does it offer?

We are considering integrating the Active Tread technology into autonomous vehicles in addition to sensor technology so that driving will be safer. Moreover, the Active Tread technology is applicable to non-autonomous vehicles and is expected to provide safety in various driving conditions.

How do the Active Tread compounds enable the tire’s physical properties to change? Why is this important?

We have incorporated reactive chemical bonds and rubber structures that are activated by water or temperature changes. In general, the performance of all the tires is linked, making it difficult to improve only one area of performance in the magic triangle. For example, improving wet grip causes a drop in RR performance. With this technology, it is possible to optimize each performance area independently of the magic triangle cycles, thanks to the active mechanical property change.

Why did you choose to speak on this topic at Tire Technology Expo and why is it important now?

There are two reasons. First, we think we can activate the R&D activities on new materials in the tire industry. Second, this is a good opportunity to find partners to start collaborative joint projects with material suppliers or other industry fields.

How significant are Sumitomo’s Active Tread compounds in terms of sustainability and enabling future mobility?

We think the Active Tread technology will be beneficial for all drivers. The Active Tread compounds will reduce the amount of resources being used by increasing the number of vehicles that no longer require a seasonal tire changeover. Furthermore, they will improve the safety of autonomous vehicles, which will benefit the future mobility society.

We expect to gain new business opportunities in raw material R&D, tire R&D and testing equipment R&D.

How groundbreaking is Sumitomo’s smart tire concept?

Our Sensing Core Technology and Performance Sustaining Technology have been recognized by the Tire Technology International Awards for Innovation and Excellence. The Active Tread technology will be our third major, unprecedented and innovative technology.

Following an engineering degree with a masters in chemical science, Tetsuya joined Technical Department IV at Sumitomo in 2011 before moving to Technical Department I. He moved to Technical Department V in 2018 and became assistant manager of Material Department III in 2021. He was promoted to manager of the material planning department in 2023.

Hear his presentation during the conference in Hannover in March 2024.

![]()