TTI discovers how Continental and Security Matters have worked together to develop invisible markers that can trace natural rubber from source to the finished tire.

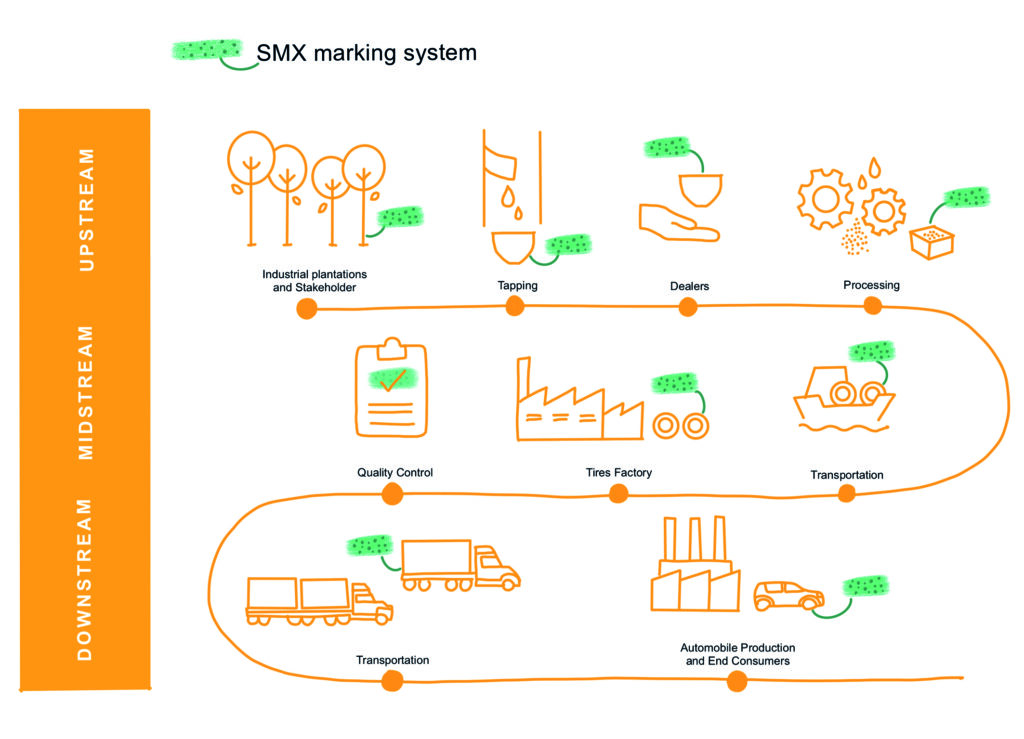

Transparency and traceability are key factors in ensuring and improving the sustainability of supply chains. Nowhere is this more apparent than in the network of rubber providers to the tire industry, with the importance of determining and verifying the origin of that rubber from the plantation to the road. Continental has been working with tech platform Security Matters (SMX) to develop a marker substance for natural rubber, able to be tracked and traced during the tire production process. At the end of 2022, Conti announced that field testing had been completed.

“Continental is testing this tamper-proof marker technology to be able to ensure that in the future the natural rubber it uses in its tires has been demonstrably grown and sourced in a completely sustainable manner,” says Claus Petschick, former head of sustainability at Continental Tires, who retired earlier this month. “As things stand today, the traceability of natural rubber supply chains is particularly challenging due to the large number of market participants, such as smallholders and middlemen. We hope to help improve that with this project.”

Continental’s goal, Petschick adds, is to source all materials used in its tire production from responsible sources by 2050.

Making a mark

Making a mark

The markers used have been developed to be harmless and are used in extremely low concentrations. Understandably, Petschick is vague on some of the specifics of the substances, as their exact nature is currently still proprietary.

“The simple compounds used are produced specifically for this application, but also occur in a very similar form in nature,” he continues. “We check very carefully that the substances fully meet our requirements in terms of safe and sustainable materials.”

With the aid of special reading devices and specially developed software, information about the rubber can be read, making it possible to determine its precise origin and, as Petschick explains, “Identification can be carried out while mobile and with comparatively little time expenditure – and also outside a laboratory environment.”

Extensive laboratory tests have shown that these markers are not altered by the manufacturing processes of the natural rubber or the tire compound, so information on the rubber’s origin is readable even in the finished tire.

Extensive laboratory tests have shown that these markers are not altered by the manufacturing processes of the natural rubber or the tire compound, so information on the rubber’s origin is readable even in the finished tire.

“The marker substances are added in very low concentrations by the smallholder when tapping the latex milk,” Petschick says of the process. “The marker can be identified non-destructively and unambiguously using the special reader and the software.

Security Matters provides the technology for marking and for the detection of markers. In addition, it offers solutions to connect data from marker readings to a blockchain database.

It’s an important step in bringing greater transparency to the industry, Petschick concludes, with the potential to operate “along the entire value chain of tires and technical rubber products”.