Andreas Giese is responsible for product planning at Falken Tyre Europe, which is owned by Sumitomo Rubber Industries. In recent years, the company has been expanding its in-house competencies while also developing its automotive product ranges, as he explains to Tire Technology International.

Can you describe the expansion of your European test facilities?

Falken, along with parent Sumitomo Rubber Industries, has expanded not only our facilities but also our resources to develop Falken tires for Europe. In 2018 we opened a 332,000ft2 facility in Hanau, Germany, to both develop and test tires and TPMS products for customers in the region. The objective was to provide local support to the growing number of European OEMs we are now working closely with, including Porsche, Audi, Mercedes and Volkswagen.

In Hanau, we have the possibility to test both compounds and tire construction in-house, which streamlines the development process and improves communication with local OEM customers and our engineering teams.

We continue to rely on the well-known test tracks, but at the end of 2019 we announced that Falken’s winter tires would now also be tested our own test track in Arnemark, Sweden. There, we have two groomed areas, each measuring about the same as three football (soccer) pitches. In addition, we have two 1.6km handling courses on snow and a further 600m ice track. We are using this facility for both OE and aftermarket tires between December and March. The flexibility of our own facility is a big help for the tires we are developing for OEMs.

As I mentioned, we continue to use other private tracks such as Idiada as well as customer facilities. For example, for the A/T3WA tire we supply to Mercedes-Benz, there is a specific test at Magna Steyr’s on the Schöckl mountain in Austria that we had to pass. That same tire was also tested at Idiada as well as some of our other preferred off-road facilities elsewhere in Spain and we did a lot of cold weather running in Austria.

Development of all season tires is a hot topic at the moment, how involved is Falken in this market segment?

Development of all season tires is a hot topic at the moment, how involved is Falken in this market segment?

All-season tires are increasingly popular in Europe and that is reflected in our development and product range. It’s a segment that is growing not only in passenger cars but also vans and light trucks, so it was only logical that we would expand our product family range in 2020.

For cars, Falken added seven new sizes to its EuroAll Season AS210 tire range this year. That takes our offer to 75 sizes, spanning 13-19in, series 40-70.

Other sectors that we think will grow in the near future include extended mobility tires. Expect to see products in this segment in the future. These offer the benefits of RFT at a lower cost entry point.

Does the company have a development program for smart tires?

Falken’s parent company, Sumitomo Rubber Industries (SRI), developed the Smart Tyre Concept to ensure that tires and peripheral services are ready for the next level. Now, we are targeting the creation of products that provide greater fuel efficiency, increased durability and improved safety, while also being more environmentally friendly.

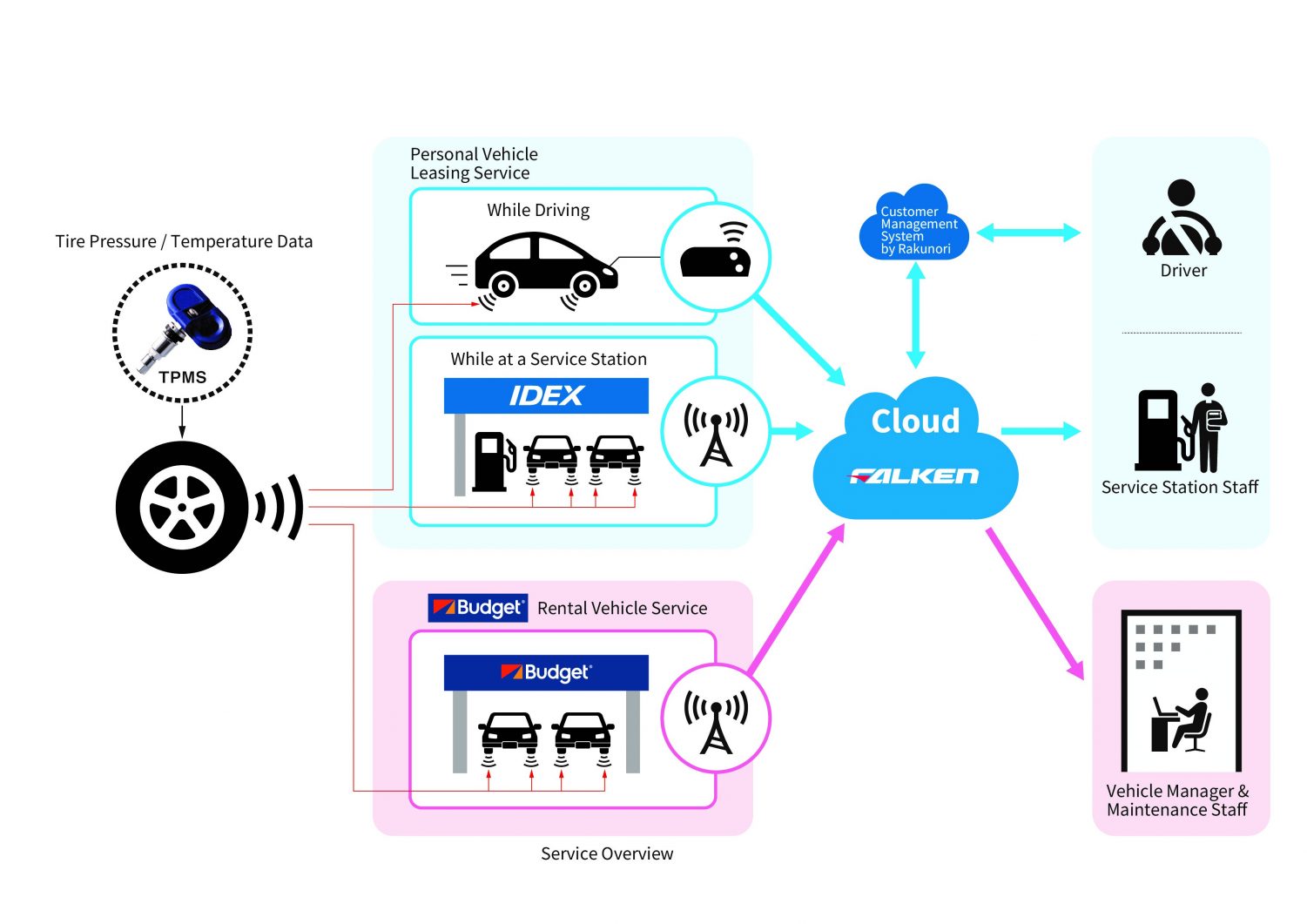

Smart Tyre encompasses many areas but our most recent testing activity is around the development of a remote tire pressure monitor system (TPMS), which will be crucial for the roll out of Level 4 autonomous vehicles. In November we completed successful proof-of-concept testing in Japan of this technology. During this test, our TPMS successfully picked up the flat tire, transmitting the data to the control center. From here, the information is automatically relayed to the nearest tire dealer, which dispatched maintenance personnel to replace the flat tire before the vehicle was then able to resume autonomous driving.

Has Covid-19 had any impact on development, manufacturing and/or supply chain issues etc?

Like every company, coronavirus is impacting our business. Fortunately, Falken’s parent company, SRI, had good product stock levels to continue supporting demand and disruption at the factories was minimal. Our flexible manufacturing strategy meant we maintain the ability to transfer production if needed, though the majority of the factories in Asia have been able to continue operating.

From a distribution perspective, we have only experienced minor disruptions. Our management teams have been incredibly impressed by the adaptability and resilience of our staff who have worked tirelessly to keep Falken operating. It has been fantastic to get feedback from our customers telling us that we were the only tire company they could get to speak to at the height of the first lockdown.

Falken has a significant motorsport presence, is this solely marketing led or is there an engineering benefit to the programs?

For Falken, motorsport is a key element of both our engineering and marketing strategies. Our Porsche is a fan favourite both at the racetrack and on social media and this year we expanded to run two 991.2s at the Nürburgring 24-hour race. That’s a key focus for our marketing to both fans and dealers but has also helped with the engineering of tires, with the ability to get more feedback from the drivers and experiment with compounds and construction.

In 2020, we also started supplying motorsport tires to other teams with our success coming quickly with Max Kruse Racing and its VW Golf. Developments we learn from our activity will ultimately cascade into our other motorsport range and where relevant, into our passenger car tires. Motorsport remains an important tool for us!